- Joined

- Dec 20, 2012

- Messages

- 9,422

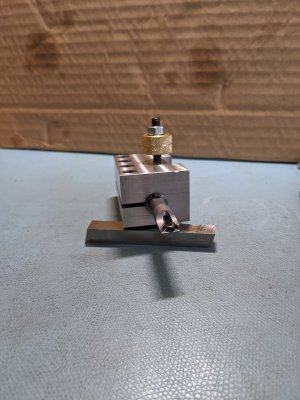

I suggest you use mild steel. 12L14 works well. I use a through slot on one side and a partial slot directly opposite the though slot; there is about 1/16" of material left in the partial slot to allow the sleeve to easily compress. So far, there has been no cracking or failure in any of my sleeves.

Robin Renzetti has an interesting design for sleeves. He uses a 3-lobe design where he mills off some material on three sides and uses a single through slot. I tried to find it but couldn't; its in one of his videos, though.

I think 10-32 is fine for this kind of holder. My holder is just over 2" long and houses 4 each, 10-32 screws. The thing is rock solid and does not allow the bar to shift. Even just snugging the screws will lock the bar solidly so if you can, use 4 screws.

Remember that the tapping drill for a 10-32 roll tap in aluminum is a #17 drill. Try it on a test piece; if it is tight, go with a #16 drill instead.

Robin Renzetti has an interesting design for sleeves. He uses a 3-lobe design where he mills off some material on three sides and uses a single through slot. I tried to find it but couldn't; its in one of his videos, though.

I think 10-32 is fine for this kind of holder. My holder is just over 2" long and houses 4 each, 10-32 screws. The thing is rock solid and does not allow the bar to shift. Even just snugging the screws will lock the bar solidly so if you can, use 4 screws.

Remember that the tapping drill for a 10-32 roll tap in aluminum is a #17 drill. Try it on a test piece; if it is tight, go with a #16 drill instead.