Hey all,

Very new to all this and need some advice.

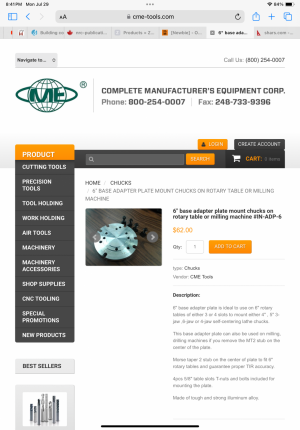

I ordered a VERTEX HV-6 (4-Slot) 6" Horizontal/Vertical Rotary Table with 4-Slot Face Plate which should arrive in a week or so.

It has a MT2 center hole. This will go on a PM727 size mill.

Am I on the right track with looking at this 6" 4 Jaw Independent Chuck and looking to just bolt it down to some t-nuts in the rotary table slots? To me, it saves me from having to drill the chuck or create some backing plate. It also allows me to run a full 6" chuck vs a 5" to allow for bolting to the table.

Thoughts/concerns? Will the chuck sit correctly on the rotary table face when fastened down?

www.shars.com

www.shars.com

Very new to all this and need some advice.

I ordered a VERTEX HV-6 (4-Slot) 6" Horizontal/Vertical Rotary Table with 4-Slot Face Plate which should arrive in a week or so.

It has a MT2 center hole. This will go on a PM727 size mill.

Am I on the right track with looking at this 6" 4 Jaw Independent Chuck and looking to just bolt it down to some t-nuts in the rotary table slots? To me, it saves me from having to drill the chuck or create some backing plate. It also allows me to run a full 6" chuck vs a 5" to allow for bolting to the table.

Thoughts/concerns? Will the chuck sit correctly on the rotary table face when fastened down?

6" 4 Jaw Independent Chuck

6" 4 Jaw Independent Chuck

More Information| Mfg SKU # | 202-5420 |

|---|---|

| Lathe Chuck Category | Independent Lathe Chucks |

| Brand | Shars Tool |

| chuck diameter | 6 |

| Thru Hole Size | 1.772 |

| mounting | plain back |

| chuck thickness | 2.559 |

| jaw movement | independent |

| Number of Jaws | 4 |

Last edited: