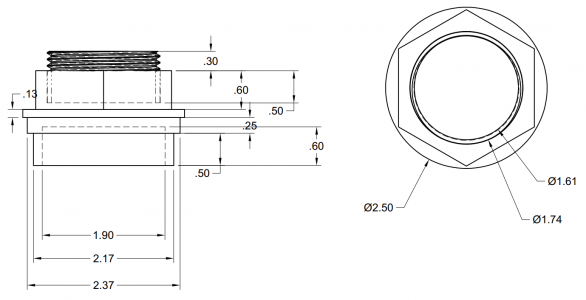

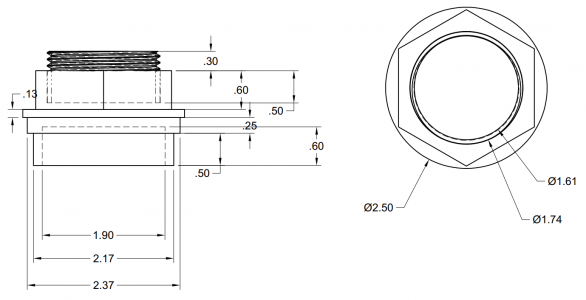

I'm going to be machining the part shown in the attached. It will be made out of one piece of 2.5"OD 6061 using my mini-mill and mini-lathe. I've been debating on the most efficient and least problematical way to machine this, which order to do each operation.

I've got to make four of these so my current thinking is to machine it from the "bottom up", and do everything up to the hex, flip it over in the chuck and do the rest with the exception of the hex, which I'll do last on the mill.

Am I just overthinking this or is there an argument for doing it in a different order?

I've got to make four of these so my current thinking is to machine it from the "bottom up", and do everything up to the hex, flip it over in the chuck and do the rest with the exception of the hex, which I'll do last on the mill.

Am I just overthinking this or is there an argument for doing it in a different order?