-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Order of Operations for Raw Castings

- Thread starter Shiseiji

- Start date

- Joined

- Apr 29, 2019

- Messages

- 2,252

In a properly designed casting the designer will have starting dimensions that locate a machined edge from a cast edge. this is the starting point and then all other machining is referenced to that first machined surface. On parts that are not profesionaly designed these critical starting dimensions are not always there. That is when you get to start eyeballing and guestimating the start point.

Of course this of no help when you have an out of tolerance casting or parts that are not properly designed and/or dimensioned to give the location of the part inside of the casting.

Of course this of no help when you have an out of tolerance casting or parts that are not properly designed and/or dimensioned to give the location of the part inside of the casting.

- Joined

- Sep 14, 2014

- Messages

- 710

- Joined

- Nov 17, 2017

- Messages

- 1,525

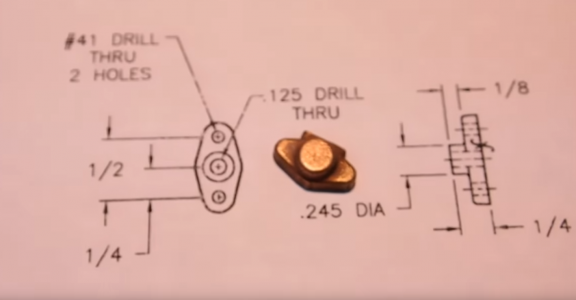

For the part shown, I would be tempted to hold it to the bed with (little) toe clamps on an expendable spacer and indicate the circular boss with a concentricity gauge, drill 7/64ths and ream to 1/8th. At that point and forward, use a 0.125 pin in that hole as your reference.

- Joined

- Apr 29, 2019

- Messages

- 2,252

Not having the part in hand I am guessing here.

It looks like the first dimension would be the 1/8 from the top of the cast flange to the height of the boss, then you have a machined surface to get the 1/4 to the bottom.

In the top view with the 3 holes the CL of the cast boss would be the starting point and then align using the the 2 end radii, drill the center hole first and locate the 2 outer holes from the machined center hole.

The info is there, it just takes practice to find it.

The reasoning for the order of flat surfaces is, the top of the boss and bottom of the flange are drawn with sharp corners, while the top of the flange is drawn with rounded corners. This indicates that the top of the flange is not machined and there is only one dimension to the cast surface so it must be the starting dimension. that starting dimension is to the top of the boss so that is the first surface machined and becomes the reference for the bottom of the flange. Since the center hole and the boss share the same center line you can then usually safely assume that it is also the cast reference for the hole locations.

Granted that once you start taking into account draft angles and uneven cast surfaces sometimes the best you can do is to eyeball things as close as possible.

It is also common that in a perfect world this all works out as the designer planned, but we are in the real world and in the real world some times you have to do things in a different order than what was designed. The biggest thing with castings is try to establish a machined X, Y and Z reference as early as possible and then do all of the machining to those references. This way all of the machined features will end up in the correct relationship to each other. IN the event that there are no starting dimensions on the drawing, make your first cuts just enough to clean up the surface, this will leave the most possible material on the other surfaces so that you do not run out of material somewhere else. Always be looking as far ahead as possible to look for what really matters to the finished part. The first cuts to a casting can take a long time of just looking at things to decide where to start.

It looks like the first dimension would be the 1/8 from the top of the cast flange to the height of the boss, then you have a machined surface to get the 1/4 to the bottom.

In the top view with the 3 holes the CL of the cast boss would be the starting point and then align using the the 2 end radii, drill the center hole first and locate the 2 outer holes from the machined center hole.

The info is there, it just takes practice to find it.

The reasoning for the order of flat surfaces is, the top of the boss and bottom of the flange are drawn with sharp corners, while the top of the flange is drawn with rounded corners. This indicates that the top of the flange is not machined and there is only one dimension to the cast surface so it must be the starting dimension. that starting dimension is to the top of the boss so that is the first surface machined and becomes the reference for the bottom of the flange. Since the center hole and the boss share the same center line you can then usually safely assume that it is also the cast reference for the hole locations.

Granted that once you start taking into account draft angles and uneven cast surfaces sometimes the best you can do is to eyeball things as close as possible.

It is also common that in a perfect world this all works out as the designer planned, but we are in the real world and in the real world some times you have to do things in a different order than what was designed. The biggest thing with castings is try to establish a machined X, Y and Z reference as early as possible and then do all of the machining to those references. This way all of the machined features will end up in the correct relationship to each other. IN the event that there are no starting dimensions on the drawing, make your first cuts just enough to clean up the surface, this will leave the most possible material on the other surfaces so that you do not run out of material somewhere else. Always be looking as far ahead as possible to look for what really matters to the finished part. The first cuts to a casting can take a long time of just looking at things to decide where to start.