- Joined

- Aug 29, 2019

- Messages

- 1,165

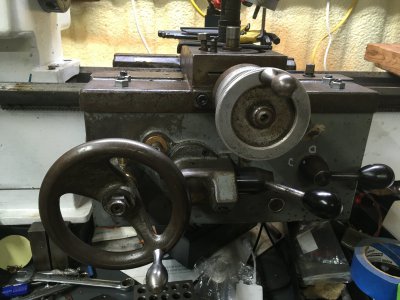

Today i fitted the apron back onto the saddle of my 5913 Clausing Lathe. A few weeks ago I re fitted the saddle to the bed using Moglice and made a new bushing for the hand wheel shaft for the apron. Both these are high wear areas on lathes. I am still impressed on how rock hard the Moglice is. The Apron is bolted up temporarily just to make sure all was going to work well with the rack gear on the bed of the lathe and it does. I will need to take it back off and clean the old gray paint off and possibly repaint it.

The saddle is not going to get painted . With all the hot chips that will be coming off while using the lathe I think paint will look worse than just the raw casting. Un decided about the apron. White to match the bed. Charcoal Gray to match the pan or just leave it raw after stripping the paint off. So what are the suggestions?

My next order of machine work is to build a new lead screw and nut for the cross slide. There is next to Zero slop between the saddle and the bed of the lathe and same with the ways of the cross slide but the nut and lead screw have at least .020 slop in them. Too much for me. I've gone this far so might as well do the rest of the job right.

Its taken me a long time to get this far but worth the time and patience to do it right. Here are just a few pics of the apron and saddle together today.

The saddle is not going to get painted . With all the hot chips that will be coming off while using the lathe I think paint will look worse than just the raw casting. Un decided about the apron. White to match the bed. Charcoal Gray to match the pan or just leave it raw after stripping the paint off. So what are the suggestions?

My next order of machine work is to build a new lead screw and nut for the cross slide. There is next to Zero slop between the saddle and the bed of the lathe and same with the ways of the cross slide but the nut and lead screw have at least .020 slop in them. Too much for me. I've gone this far so might as well do the rest of the job right.

Its taken me a long time to get this far but worth the time and patience to do it right. Here are just a few pics of the apron and saddle together today.