- Joined

- Sep 28, 2013

- Messages

- 4,394

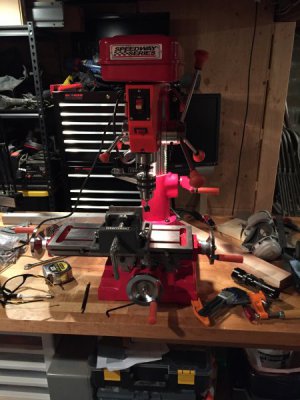

Gulf Oil colors

doh! that's what I was thinking of. The shame, the shame

Gulf Oil colors

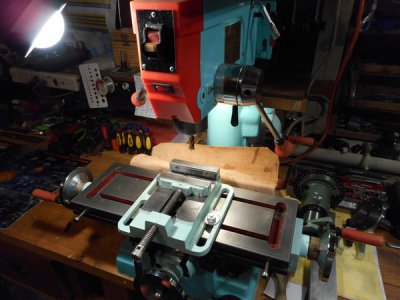

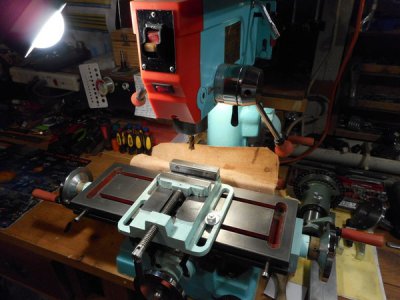

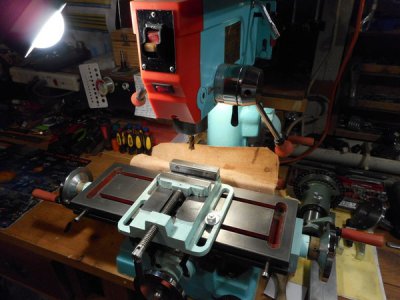

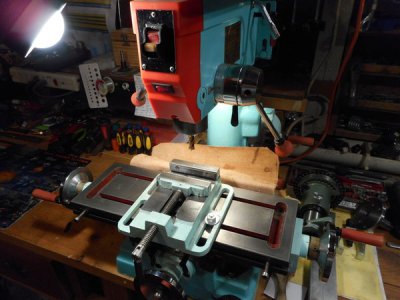

That looks more like a drill press with a positioning table than a milling machine, however using small cutters (less cutting force) in the chuck should be just fine if you keep your cuts small.

Great job with the new paint and cleanup!

Earlier this summer, I dug my mill out of my parent's basement. It's been sitting there unassembled for over a decade. Here's the information I found on it.

Drill/Mill Machine

Speedway Series (Homier)

Model:

DTMACH 34-03989

Motor:

3/4 HP, 56 frame, 10.6 A

Lever handles:

M12 x 1.75 mm

Revolving Handles:

M10 x 1.5 mm

Taper:

MT2 taper

Included Stock Arbor:

MT2 taper to B18 with M10 drawbar thread

Included Stock Drawbar:

M10 x 1.50 mm x 275 mm

Replacement Imperial Drawbar:

3/8"-16 x 10-3/4"

Speed:

390-480-600-780-960-1080-1620-1750-2150-2280-3259-3950

Max. Drilling Capacity:

5/8" (16 mm)

Max. Diameter of Vertical Milling:

1/2" (12 mm)

Max. Width of Face Milling:

1-1/2" (40 mm)

Table slots:

7/16"

Table movement:

9-3/4" x 4-3/8"