-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- GENERAL TYPES OF METALWORKING MACHINES

- ANTIQUE & VINTAGE MACHINERY

- MISC ANTIQUE & VINTAGE MACHINERY

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old Craftsman band saw

- Thread starter yota

- Start date

80" long. not sure of the rest yet.What size blades (thickness, width, length) does it take?

cleaned it up today inside and out. used a brush and compressed air then used rags and my killer yellow citrus cleaner, then wiped it down with zylene and then a damp rag rinse. couldn't believe the grime that came off. much nicer color now. may not have been cleaned in 60 years.

sanded the cast iron table down with the random orbit to remove surface rust. gave table and saw 3 coats of Colonite Fleet Wax. that was some thirsty paint.

sanded the cast iron table down with the random orbit to remove surface rust. gave table and saw 3 coats of Colonite Fleet Wax. that was some thirsty paint.

Yota, looks like our paths have crossed again. I too have an old Craftsman bandsaw I have converted to cut metal. It works very well, I love it. I put a DC motor and a treadmill mill controller on it so I can adjust the speed to cut metal or wood. It did buy a good blade for it and put new tires on it too. I did make a new blade guide using ball bearings. The motor will run full speed at 2500 RPM so I geared it to do about 1450 FPM at that speed which is good for wood. I simply turn the speed pot down and run it at about 500 RPM which is about 300 FPM that works good for metal. It's just a 12" machine so I use it just on small stuff. I have a large horizontal band saw for larger stuff.

![IMG_9049[1].JPG IMG_9049[1].JPG](https://www.hobby-machinist.com/data/attachments/341/341719-8d07d0332c42ecf8fa96e5333e9238a8.jpg)

![IMG_9050[1].JPG IMG_9050[1].JPG](https://www.hobby-machinist.com/data/attachments/341/341720-344daa889c39fad3a9e7826b4d262ced.jpg)

![IMG_9051[1].JPG IMG_9051[1].JPG](https://www.hobby-machinist.com/data/attachments/341/341721-c6c52ed292aa22339b8877c3033b7abd.jpg)

![IMG_9049[1].JPG IMG_9049[1].JPG](https://www.hobby-machinist.com/data/attachments/341/341719-8d07d0332c42ecf8fa96e5333e9238a8.jpg)

![IMG_9050[1].JPG IMG_9050[1].JPG](https://www.hobby-machinist.com/data/attachments/341/341720-344daa889c39fad3a9e7826b4d262ced.jpg)

![IMG_9051[1].JPG IMG_9051[1].JPG](https://www.hobby-machinist.com/data/attachments/341/341721-c6c52ed292aa22339b8877c3033b7abd.jpg)

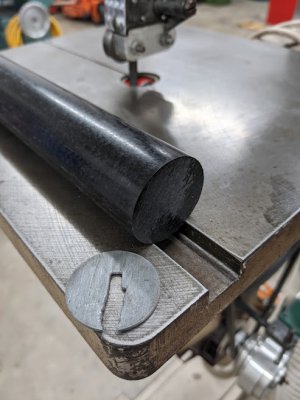

got 3 Lennox bimetal blades in 1/2" 10/14 tpi, 3/8" 14/18 tpi and 1/4" 14/18 tpi. adjusted all the blade guides. the manual says the blade tension is "set at the factory, no adjustment needed". ha. so loose. I removed the upper wheel assembly and cut this section off the steel tube that a tension bolt goes thru (only there to slack tension for changing blades). this allowed me to tighten it down to correct tension. cut a pc of 1/4" angle iron. worked really well.

Last edited:

the leveling feet were like 1 1/2" dia and pivoting type. very tippy. I took 4 hockey pucks, cut some 3/16 thick stainless steel discs (drilled and tapped them) and used the stock adjusting bolts with high strength locktite . glued the pucks to the stainless discs with 3m 5200. the cast iron base is also threaded where the adjusting bolts got thru. very stable now.

Last edited: