- Joined

- Aug 5, 2015

- Messages

- 276

Opening up an old thread after "pondering" for awhile.

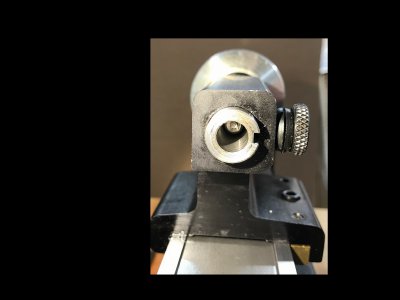

My Sherline tailstock, to be in better alignment to the headstock (after the headstock is independently aligned very very well to the ways) needs to move TOWARDS the operator (front of lathe). It can't do that because of the design. AND when the tailstock spindle is locked with the tailstock locking screw, it pushes the spindle AWAY from the operator. That makes the alignment worse. Since the tailstock is pushed away from the operator and the cutting tool, the shaft being cut will be bigger on that end than on the headstock end.

WHAT IF the tailstock locking screw was relocated to the backside? That would improve the alignment somewhat, I think.

Of course the spindle itself would then be upside down so you can't read the scale on it,, so the locking screw would engage the keyway,

Have any of you Sherline owners tried moving the locking screw to the back side? I am thinking about it and might try it.

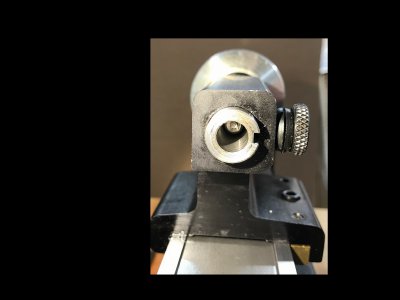

My Sherline tailstock, to be in better alignment to the headstock (after the headstock is independently aligned very very well to the ways) needs to move TOWARDS the operator (front of lathe). It can't do that because of the design. AND when the tailstock spindle is locked with the tailstock locking screw, it pushes the spindle AWAY from the operator. That makes the alignment worse. Since the tailstock is pushed away from the operator and the cutting tool, the shaft being cut will be bigger on that end than on the headstock end.

WHAT IF the tailstock locking screw was relocated to the backside? That would improve the alignment somewhat, I think.

Of course the spindle itself would then be upside down so you can't read the scale on it,, so the locking screw would engage the keyway,

Have any of you Sherline owners tried moving the locking screw to the back side? I am thinking about it and might try it.

Last edited: