Hi All

I need to bore a 1.5 inch hole through a thick hunk of 6061 on an Enco 9x20.

Stock 4 jaw chuck.

How much slop should be on the faceplate bolts? I have it as close to zero by feel without binding as I can.

Do these need to be tightened and when during setup? But if you get them too tight the adjusters wont work right.

My first attempt made a beautiful hole but the stock shifted. I think I caught that before it was too late to save the piece. I was just having too much fun in the moment. lol

The sides of the hole are square to the top at least.

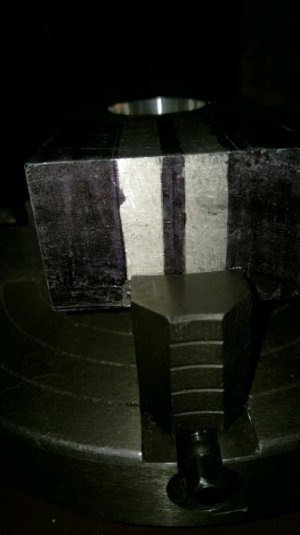

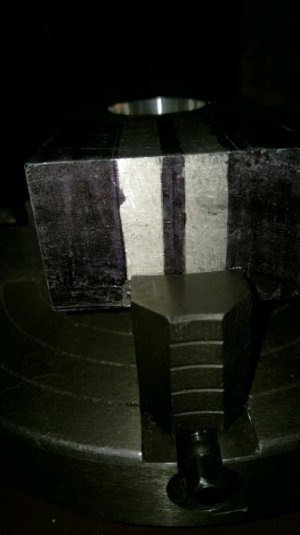

I have attached some photos of first setup for critique. Its also sat like that for the last 3 years. I need to make some progress. lol The first 2 you can see the scrape marks from the jaws when it shifted. There is a circle scribed on top where the hole is supposed to be. Luckily, the hole isn't outside of that.

Sooo, what went wrong here?

I need to bore a 1.5 inch hole through a thick hunk of 6061 on an Enco 9x20.

Stock 4 jaw chuck.

How much slop should be on the faceplate bolts? I have it as close to zero by feel without binding as I can.

Do these need to be tightened and when during setup? But if you get them too tight the adjusters wont work right.

My first attempt made a beautiful hole but the stock shifted. I think I caught that before it was too late to save the piece. I was just having too much fun in the moment. lol

The sides of the hole are square to the top at least.

I have attached some photos of first setup for critique. Its also sat like that for the last 3 years. I need to make some progress. lol The first 2 you can see the scrape marks from the jaws when it shifted. There is a circle scribed on top where the hole is supposed to be. Luckily, the hole isn't outside of that.

Sooo, what went wrong here?