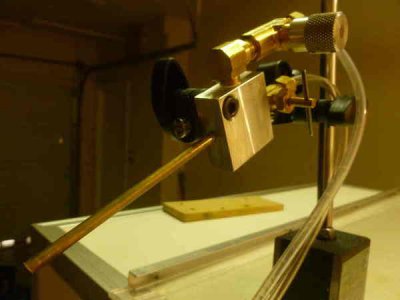

Thanks Michael!! I think they would be well worth looking into. I found that the little rubber o-ring in the valves that I used is what is causing the problem there. When you stop turning the screw, the rubber pulls it back slightly, making it difficult to get it set correctly.

JPigg55, it certainly will not hurt to experiment a little. That's how these sorts of projects get better! I've still got the original nozzle on mine and it works just fine. As for the flex nozzle, I think it will give you trouble. Another member tried that some time back and the moving air was unable to carry the droplets inside that 'rough' tube. Straight, laminar flow seems to be an important part of making it work properly. With the flex line the coolant dropped out of the air and built up inside the nozzle until the air could manage to 'grab' it again and spit it out in spurts. Not trying to discourage you, but just letting you know what we saw happen before.