To take things as they are in my mind, (backwards as usual) a "green wheel" grinder stone MAY be available as a "flap disk", I don't know. They are normally configured as grinding wheels, same as what comes on a bench grinder. I'm sorry, I'm half asleep as I write this. I don't think clearly this time of day.

The material of a regular grinding wheel is good for steel(iron) but when used for softer metals, the metal tends to melt off little pieces that imbed in the wheel. The end result is when the wheel builds up heat and/or grinding effiencey gets lower, the wheel will crack internally. In a worst case scenario, the wheel will come apart. In a less dangerous scenario, small bits of the soft metal are thrown off. The green wheel is of a different material that grinds down the surface as it is doing "its' thing". In a commercial setting, OSHA requires green wheel use for grinding any "non ferrous" metal.

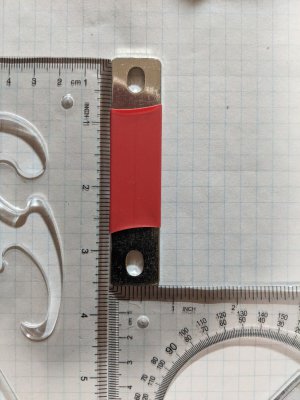

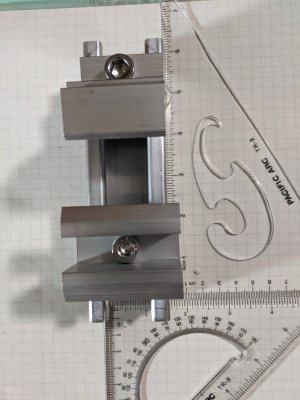

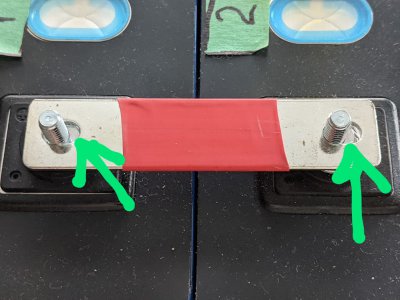

Now, on spacing and the buss bars, and other miscellaneous details of the batteries. . . The buss bars have elongated holes probably because they fit many different configurations. There must be a little space between the batteries. Just ambient temperature will have the usual side effect of expansion when hot. When they are racked up, temperature is near ambient. As they are working, discharging or charging, the internal temperature tends to rise above ambient, hence pressure. The batteries can stand being pressed together, they're plastic and there is some give as they expand. But if they expand that last little bit, the plastic tends to fuse. A pain in the wazoo to break things down for maintenance. And dangerous. . .

There is a "seperator" sheet sold for that particular purpose. Sort of like a cardboard box, but a rubber like material. Crushable so expansion is taken up. For my own projects at home, I just use a little spacing. Things like that usually aren't a problem until that unhappy time when you do need them. Then they pay off, with interest.

As far as UniStrut goes, the aluminium is somewhat deformable. If you use a steel nut, it will deform the strut somewhat as it is tightened. That is the reasoning behind that little "curl" along the edge. The big issue there is the galvanic corrosion between the aluminium and the steel. Aluminium nuts are the quick answer for that, but aluminium nuts won't stand near as much torque as steel. Some form of resistance between the two metals is vital. If nothing else, a grease between the two will slow the process considerably.

Unless you live near salt water, then all bets are off. In the '80s I worked overseas, on an island, for the US government. The local engineer had specified aluminium rigid conduit (Sched 40) for electrical installations. But the normal installs involved couplings and other fittings that the purchasing agent, who didn't know any better, had bought steel because the price was lower. The conduit only lasted a couple of years, then corroded to the point where a storm would rattle hanging conduit, cutting the wires. I only worked the job a year or so, but had to make repairs to many installations where galvanic corrosion had taken its' toll.

In 2005, I was badly burned when an industrial UPS (USSteel) caught the batteries on fire. A salesman convinced my boss that the new, miracle batteries would work fine. They didn't. . . When a power failure transferred the UPS, it attempted to start a few hundred HP worth of hydraulic pumps. The battery bank (seriesed for 240 volts) blew up and caught fire. Right next to where I was working. My only way out was through the battery room. I had other routes, but when the power failed I headed for the substation, not a safety point.

I didn't get my skin burned, but my lungs are shot from the acidic smoke. Ces't la Vie ($#|t happens) Safety is one thing, but when one is dealing with a couple hundred tons of molten steel, safety regulations go out the window. You do what you gotta do to keep the steel contained. The bottom line is I personally don't trust those miracle batteries when they take a heavy load. The 3-71 Detroit finally started and took the load. But the batteries melted. . .

I could go on and on about "web ex-spurts"(has been drips under pressure) and their lack of foresight. But this tretease has gone on far too long already. Just think ahead for worst case situations and set aside what little makes sense.

.