-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me..........Emco Compact 8 Lathe

- Thread starter liteace

- Start date

- Joined

- Nov 14, 2016

- Messages

- 3,345

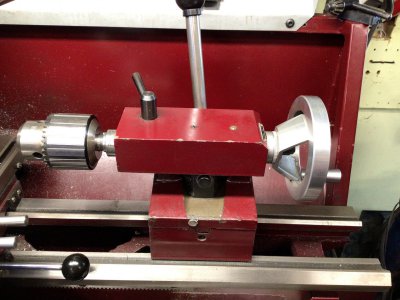

Looks like it came with a Multifix toolpost, if that is a real Swiss made one that is a nice bonus, but even the copies are not cheap.

https://www.penntoolco.com/swiss-mu...vpm0NGcszZo1NP-UATCv1oKphpEEvZ7gaAhgKEALw_wcB

https://www.penntoolco.com/swiss-mu...vpm0NGcszZo1NP-UATCv1oKphpEEvZ7gaAhgKEALw_wcB

This is the tool clamps I have, 3 of these

www.hoffmann-group.com

www.hoffmann-group.com

The tool holder is this, cant seam to find a lot of info on it

Quick-change turning toolholder AA12/50 | Hoffmann Group

Buy Quick-change turning toolholder AA12/50 at the Hoffmann Group eShop: ✓ Personal advice ✓ Exclusive top products

The tool holder is this, cant seam to find a lot of info on it

- Joined

- Nov 14, 2016

- Messages

- 3,345

This is the tool clamps I have, 3 of these

Quick-change turning toolholder AA12/50 | Hoffmann Group

Buy Quick-change turning toolholder AA12/50 at the Hoffmann Group eShop: ✓ Personal advice ✓ Exclusive top productswww.hoffmann-group.com

View attachment 384111

The tool holder is this, cant seam to find a lot of info on it

View attachment 384112

German is good, I was thinking Chinese when I mentioned the copies.

You got any pics you can post, I'd like to modify the tailstock lock as its a pain as isI don’t know the technical name for the bolt, pivot bolt? But most of that style of QCTP I see has just a nut on it. So the Allen head would be an improvement as far as clearance IMHO As there’s not much clearance between it and the height adjustment. Personally I’d make another bolt with a head like the locking stud uses so I could use that same handle on both of them.

My clone came with an AXA style QCTP and they made a nut with a handle on it. It works but having two handles so close together took a little getting used to and sometimes it interferes. Yours the handle isn’t attached so it would be easy to swap.

The unmodded thing on my 9x20 clone was the nut on the tailstock lock. I took a camlock kit meant for the 7x lathe tailstock and adapted it to my tailstock. Made life so much easier as I move the tailstock a lot!

- Joined

- Feb 9, 2017

- Messages

- 5,610

I used the kit from Little Machine Shop to mod the 7x lathe tailstock.You got any pics you can post, I'd like to modify the tailstock lock as its a pain as is

Tailstock Cam Lock Kit | Lathe Cam Lock Kit | LittleMachineShop

Compatible with a variety of lathes, this cam lock kit can covert a standard mini lathe tailstock to lock by lever action. Get the job done right.

It was one of my first big projects with my mill/drill. I hope you can see the material on inside top of the tailstock frame so the eccentric had room to work and then bore through for the eccentric. I used one of the drill arms off my mill as the handle. Overall it’s been a really good project and way better than it was with the silly locking bolt/wrench. The problem is the groove/ramp? underneath the frame the bolt engages with was not machined parallel to the ways. So where the handle locks is not the same depending on where you are on the ways. The final mod I need to make is a new bottom retainer for the locking bolt as its silly and often goes cockeyed because it has a slot for the bolt head. Hope this helps.