- Joined

- Jun 11, 2013

- Messages

- 731

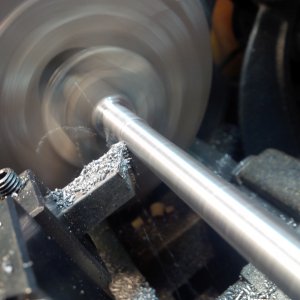

So with everything trammed up I figured I would try to mill something. I found that everything just jumped around everywhere. Nothing smooth at all. Tried to dial in the perfect speeds etc and nothing worked. So I noticed some vertical play in the quill and tried to tighten things down a bit more (I really had it fairly loose before) and I noticed everything released on the drawbar and holder. Pulled the drawbar out and noticed the roll pin was broken and there were only 2 threads hitting the holder. At least 5 threads were gone.

I am going to make a new longer drawbar. The current one is mild steel. Any reason I would want to go harder with the drawbar? Should I use the rollpin like the orig or make the whole thing solid? Right now it is a hex 19mm top piece on the rod with a rollpin holding the hex head.

Thanks for any comments.

I am going to make a new longer drawbar. The current one is mild steel. Any reason I would want to go harder with the drawbar? Should I use the rollpin like the orig or make the whole thing solid? Right now it is a hex 19mm top piece on the rod with a rollpin holding the hex head.

Thanks for any comments.