-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me 2001 Haas TM1

- Thread starter slodat

- Start date

No, my project is on long term hold. My parents have moved in, and until we get their house built, no spare change much less $$ for anything else.Thank you. Did you get a CNC milling machine yet? I remember talking last year about you looking for a machine.

All in all I'm blessed to have them alive and healthy, but in the mean time I make due with my 3d printer, farm projects and living vicariously though this site.

- Joined

- Jan 20, 2021

- Messages

- 296

Started setting up the Orange vises on the Haas. Quickly realized I needed to buy more T-Nuts, and the correct length SHCS. It's crazy how that stuff cost a little over $100. The table travel is 30X x 12Y. So, I could put a third vise on the table and have plenty of lead-in/lead-out room. For now I'll center them. 246 blocks make that easy. I'll indicate them in once I have the hardware to bolt them down.

I bought an ultrasonic cleaner to help clean up the grimy tooling that came with the Haas. It did a great job. The tooling is all name brand, high quality stuff. Now it isn't nasty, making a mess any time I touch it. The threads work better as well.

Some of the tools for the Haas getting made up after a good cleaning and shot of LPS.

I bought an ultrasonic cleaner to help clean up the grimy tooling that came with the Haas. It did a great job. The tooling is all name brand, high quality stuff. Now it isn't nasty, making a mess any time I touch it. The threads work better as well.

Some of the tools for the Haas getting made up after a good cleaning and shot of LPS.

Last edited:

- Joined

- Jun 13, 2022

- Messages

- 1

Hi Slodat I just got 2001 Tm-1 too. I am not knowledgeable on these machines and would be great for anything you could share regarding your experience getting it up and running. I plan to try to energize it this coming weekend and get the ball rolling to get it up and running.

Attachments

- Joined

- Jan 20, 2021

- Messages

- 296

Excited to see another TM1 owner on here! Keep us posted on how it's going!Hi Slodat I just got 2001 Tm-1 too. I am not knowledgeable on these machines and would be great for anything you could share regarding your experience getting it up and running. I plan to try to energize it this coming weekend and get the ball rolling to get it up and running.

- Joined

- Jan 20, 2021

- Messages

- 296

Working on mounting the Fogbuster nozzles on the Haas. I'm going to use existing fastener locations for the factory chip shield. It's not doing much and coolant is much more important to me.

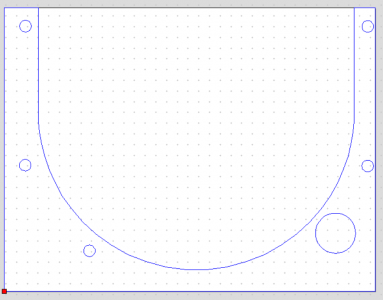

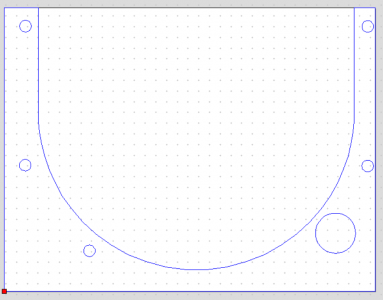

I scanned the factory part on the flatbed scanner, imported into CAD so I could use it for reference geometry.

Reference geometry:

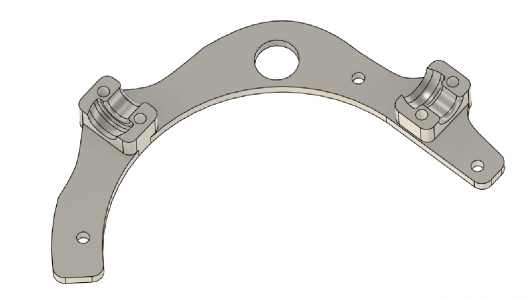

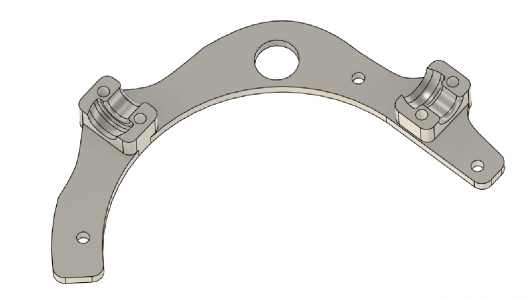

This was imported into Fusion 360, and I started whittling away. I combined the loc-line mounts into the part.

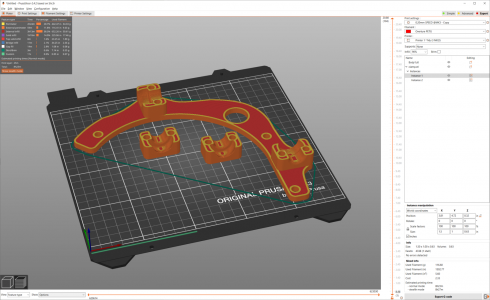

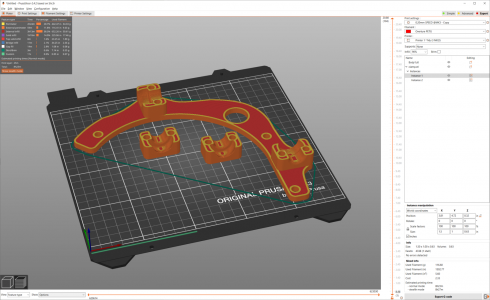

Next up is the slicer:

Now, we wait. Will be ready for me when I get to the shop in the morning.

I scanned the factory part on the flatbed scanner, imported into CAD so I could use it for reference geometry.

Reference geometry:

This was imported into Fusion 360, and I started whittling away. I combined the loc-line mounts into the part.

Next up is the slicer:

Now, we wait. Will be ready for me when I get to the shop in the morning.

Last edited:

- Joined

- Jan 20, 2021

- Messages

- 296

- Joined

- Jul 29, 2015

- Messages

- 93

Can't have too many tool holders! Nice cart, and nice shop!