This project has been on hold, in part waiting for the price of lumber to come down. I also had some medical issues that ate up much of June. I have my 6 month post-cancer checkup coming up in a couple of weeks. This will be four years out from finishing radiation treatment. There is always a bit of dread associated with these checkups. Of course with each 6-month checkup the chance of recurrence goes down somewhat. I was enough of an odd case that it is really hard to pin odds on my case.

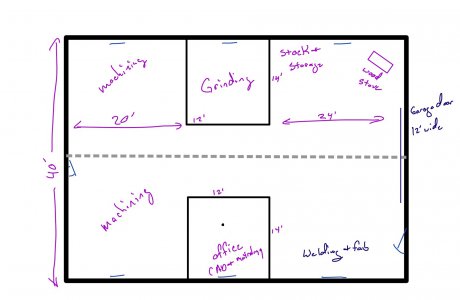

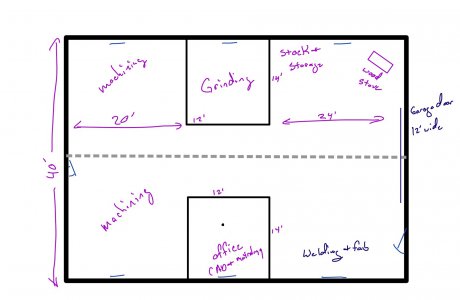

Anyway, I've decided that once I come back from the Sept 10 checkup, I'm going to start pricing construction. Likely I will go with stick-frame by a local Amish crew, fairly big outfit that does a lot of work in this area. I was originally thinking 40x64, but I've scaled it back to 40x56x12 to keep the cost down a bit, and to fit the site better. I already have a layout in mind:

Basically I'll have a crew pour the slab, frame up and side the building. Then I'll do interior framing, additional insulation, wiring, etc, myself. Six windows, three each along the long walls, a 12' wide garage door and entry door on the North (right side of image), and a back entry door on the South side. I'll put in a mini-split/ductless unit, probably one that will handle two indoor units, a small one for the office and larger for the machining area, possibly a third for the welding area.

I plan on eventually putting a light duty bridge crane in, spanning the whole building. The space between the two interior rooms gives enough width (12') to move machines in/out.