- Joined

- Jan 20, 2016

- Messages

- 602

After getting some Christmas money and making a few extra bucks with a machining job, I decided to get a new milling machine. I currently have a Harbor Freight X2 that I have had for a little over 2 years now. I will be converting the PM-25 to CNC immediately. I intend for this thread to be similar to my PM1030v thread where I try to share details about the machine that I didn't find before buying it, get help with things that aren't quite right, and share what I find the machine is capable of.

I currently have all the CNC components from my X2 and they should be sufficient for the PM-25, except the X axis ball screw which will only allow for 17 inches instead of the full 20. That will be replaced relatively soon.

It will be converted and upgraded in 3 stages.

1. CNC Retrofit

-400 oz-in steppers on each axis

-1605 single nut ballscrews

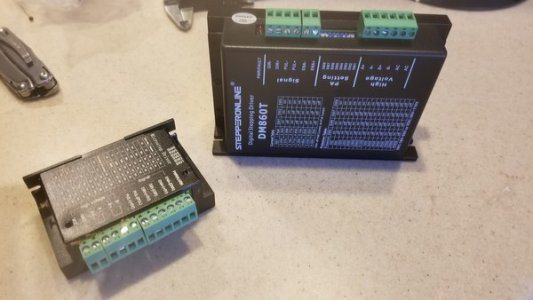

-TB6600 drivers

-Control with LinuxCNC

2. Automatic Tool Changer + Spindle speed increase

-10 Tool Umbrella Changer

-Pneumatic Cylinder

-TTS Style Holders

-Angular Contact bearings in the spindle

-New Pulleys

3. Full Enclosure similar to Tormach 440

A few reasons I chose this mill specifically:

1. PM customer support and 3 year warranty. After my experience with the lathe, their quick responses (The longest it ever took to get a reply was 12 minutes), and their quick shipping of parts covered under warranty.

2. Most parts from my X2 can be reused for the CNC, then I can revert the X2 to manual.

3. Size. My shop is currently a 2 car garage that needs to be able to get a car in if necessary. Right now I have 2 lathes, a mill, a grinder, a work bench, drill press, and band saw in there and it is getting full.

4. Belt Drive. I was also considering the G0704 and PM-727. I didn't want to have to deal with making a belt drive for the spindle or taking apart the head to get the gears out.

5. 120V power. I was considering the PM-30MV because it has a 2 HP motor instead of 1, has a few extra inches of travel in each direction, and weights nearly double what the PM-25 weighs. But with 220v power and a breaker box that is full, I would need to hire an electrician to either put in another breaker box or rewire it somehow to make space. With the cost of the rewiring, the need to buy all new CNC components, and the extra cost of the mill, it got pushed too far out of my budget.

The machine shipped yesterday and I got the call this morning that it will be delivered this afternoon. If the truck arrives before 4:06 PM, it will have shipped from PA to NC in less than 24 hours. I elected for the lift gate delivery this time since I no longer have access to a truck and a trailer.

I have plans for some extras for this machine that I think will be fun.

1. 4th axis, either a trunion table or just a chuck.

2. New spindle for a BT-25ish tool or something entirely custom.

3. Servos (maybe)

4. A touch probe

5. Flood coolant

6. A control panel

Right now, the delivery is scheduled for between 4pm and 6pm, with the estimated arrival time of 4:26 to 4:35. I will post pictures and more details this evening when it gets here.

I currently have all the CNC components from my X2 and they should be sufficient for the PM-25, except the X axis ball screw which will only allow for 17 inches instead of the full 20. That will be replaced relatively soon.

It will be converted and upgraded in 3 stages.

1. CNC Retrofit

-400 oz-in steppers on each axis

-1605 single nut ballscrews

-TB6600 drivers

-Control with LinuxCNC

2. Automatic Tool Changer + Spindle speed increase

-10 Tool Umbrella Changer

-Pneumatic Cylinder

-TTS Style Holders

-Angular Contact bearings in the spindle

-New Pulleys

3. Full Enclosure similar to Tormach 440

A few reasons I chose this mill specifically:

1. PM customer support and 3 year warranty. After my experience with the lathe, their quick responses (The longest it ever took to get a reply was 12 minutes), and their quick shipping of parts covered under warranty.

2. Most parts from my X2 can be reused for the CNC, then I can revert the X2 to manual.

3. Size. My shop is currently a 2 car garage that needs to be able to get a car in if necessary. Right now I have 2 lathes, a mill, a grinder, a work bench, drill press, and band saw in there and it is getting full.

4. Belt Drive. I was also considering the G0704 and PM-727. I didn't want to have to deal with making a belt drive for the spindle or taking apart the head to get the gears out.

5. 120V power. I was considering the PM-30MV because it has a 2 HP motor instead of 1, has a few extra inches of travel in each direction, and weights nearly double what the PM-25 weighs. But with 220v power and a breaker box that is full, I would need to hire an electrician to either put in another breaker box or rewire it somehow to make space. With the cost of the rewiring, the need to buy all new CNC components, and the extra cost of the mill, it got pushed too far out of my budget.

The machine shipped yesterday and I got the call this morning that it will be delivered this afternoon. If the truck arrives before 4:06 PM, it will have shipped from PA to NC in less than 24 hours. I elected for the lift gate delivery this time since I no longer have access to a truck and a trailer.

I have plans for some extras for this machine that I think will be fun.

1. 4th axis, either a trunion table or just a chuck.

2. New spindle for a BT-25ish tool or something entirely custom.

3. Servos (maybe)

4. A touch probe

5. Flood coolant

6. A control panel

Right now, the delivery is scheduled for between 4pm and 6pm, with the estimated arrival time of 4:26 to 4:35. I will post pictures and more details this evening when it gets here.