- Joined

- Mar 5, 2019

- Messages

- 216

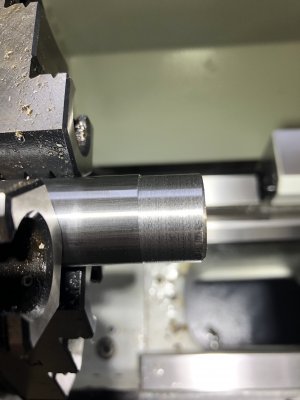

i cut a lot of stainless on my Grizzly 4003G, the 2" stock i start with is often spinning at 800 RPM, cutting .030 - .040 with a medium feed rate and comes out beautiful.. as i get smaller i spool it up to 1000 rom. using carbide insert tooling.

I've recently been cutting 2.25" CRS with the same carbide, spinning it as fast as my lathe will go, 1400, coming out like a work of art at .030, again medium feed rate (not sure what that number is) but big, hearty chips flying.. i often where a full face shield when doing those cuts...

As said before: speed may need to be faster, DOC a little deeper .. and remember.. "a little cardio never hurt anybody"

I've recently been cutting 2.25" CRS with the same carbide, spinning it as fast as my lathe will go, 1400, coming out like a work of art at .030, again medium feed rate (not sure what that number is) but big, hearty chips flying.. i often where a full face shield when doing those cuts...

As said before: speed may need to be faster, DOC a little deeper .. and remember.. "a little cardio never hurt anybody"