- Joined

- May 3, 2020

- Messages

- 189

Sure thing.

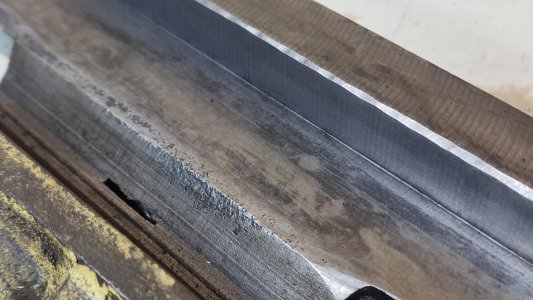

And zoomed in further on that rear trapezoidal way surface:

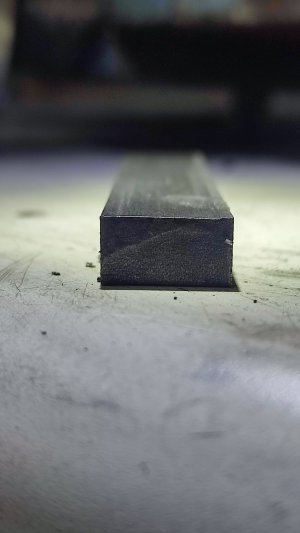

And a view from the side as well:

My phone camera is not the best, so hopefully this makes it a little more clear what I'm referring to. I can see multiple ridges on the way surface as well as what appears to be raw cast iron, not machined at all. Got missed in QC I guess?

Here are some views better explaining what I'm showing here. This is a view of the underside of the saddle. The rear way surface can be seen near the top of it:I'm having problems identifying things in that first pic.

Can you do other angles, and also a little further out to see what area you are zooming in on?

And zoomed in further on that rear trapezoidal way surface:

And a view from the side as well:

My phone camera is not the best, so hopefully this makes it a little more clear what I'm referring to. I can see multiple ridges on the way surface as well as what appears to be raw cast iron, not machined at all. Got missed in QC I guess?