-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 3 Phase Motor/VFD for my RF45 Mill

- Thread starter SnakeyJ

- Start date

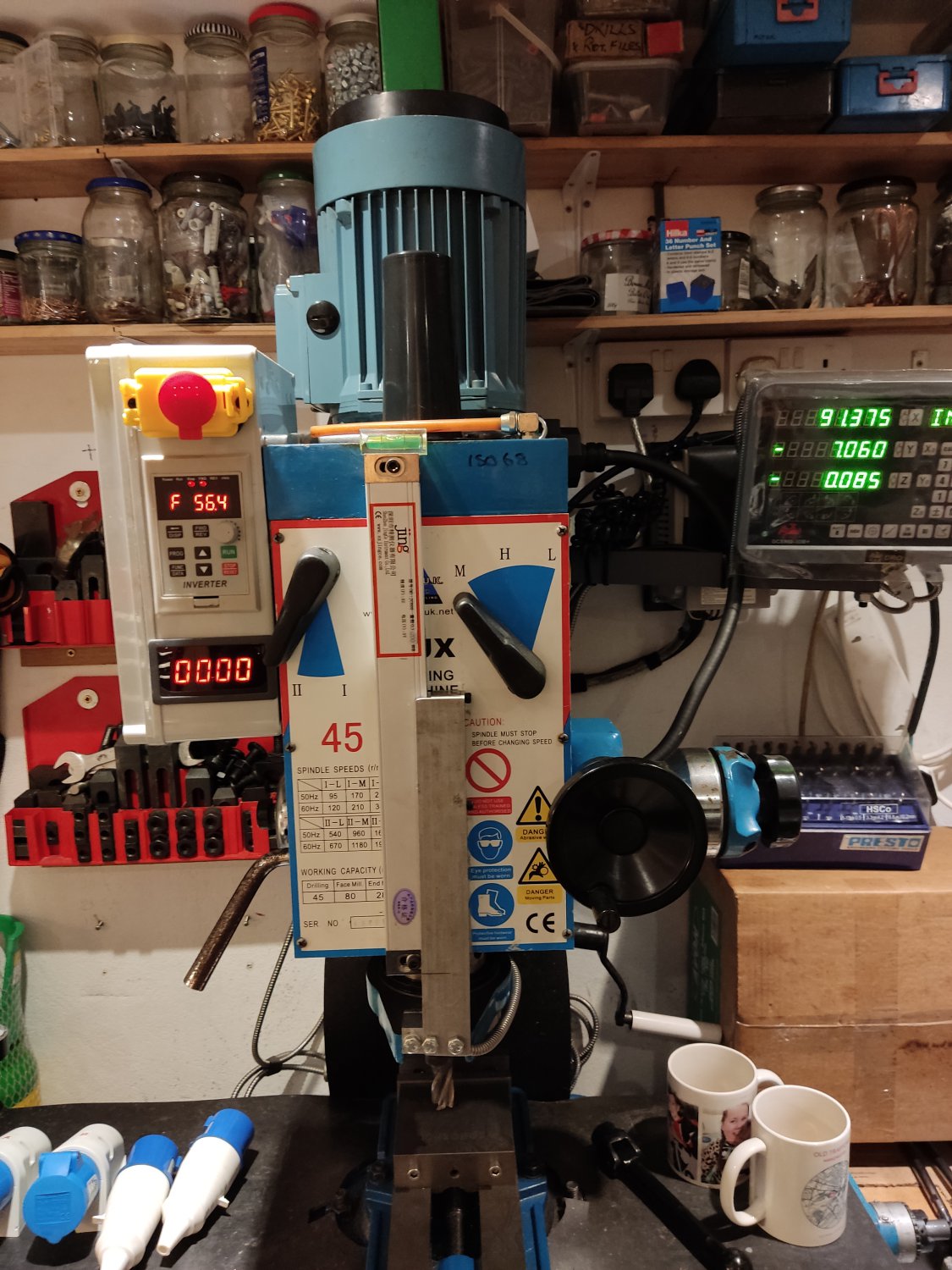

Finished machine - I may replace the vfd controls in future, but working well over last three months:

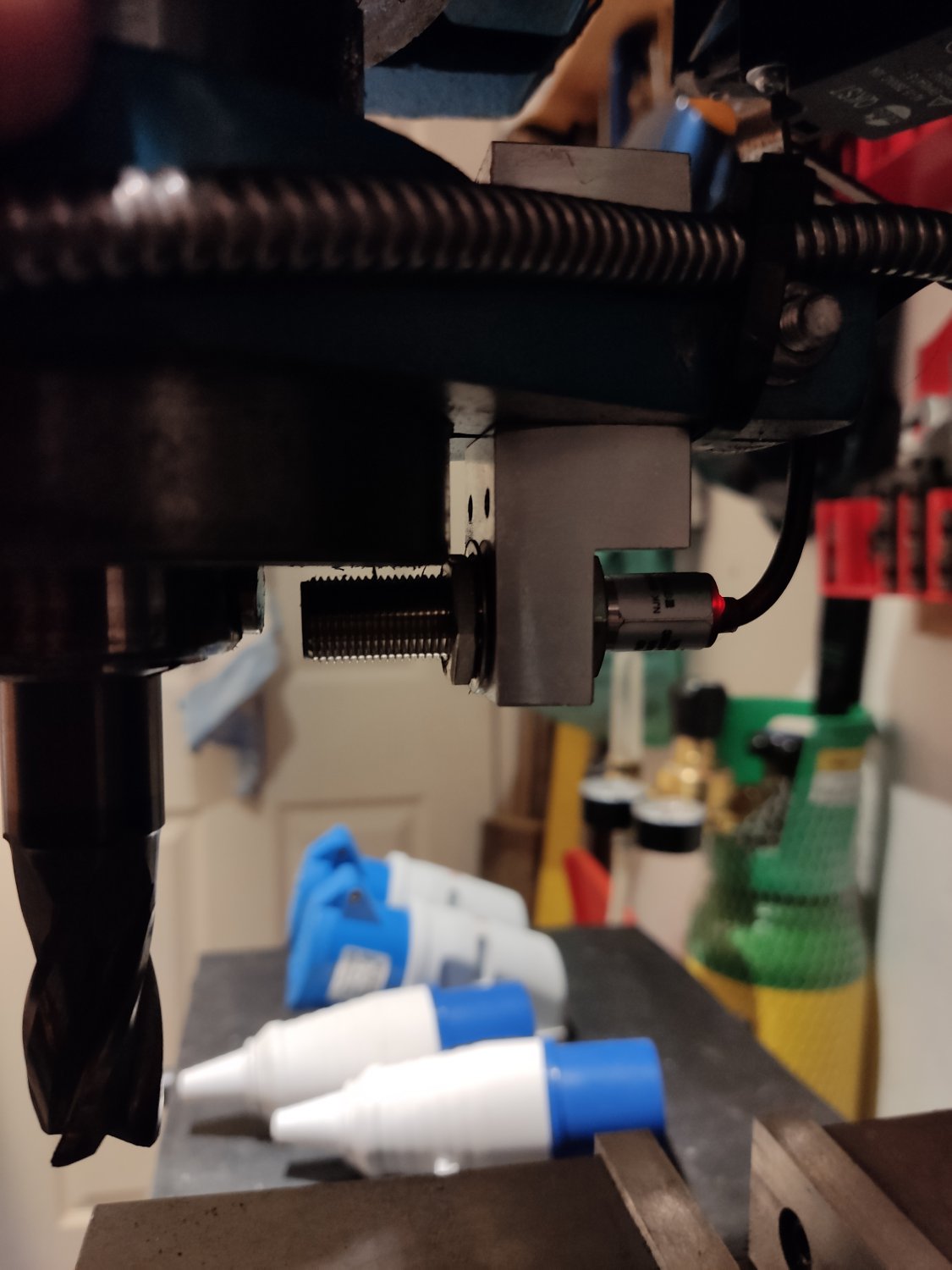

The hall effect RPM guage needs a little tweak to reduce distance, but does work. The drawback is that the magnet picks up iron and steel swarf. Ok as a one off to check speed ranges, but an optical sensor might be a better option:

The hall effect RPM guage needs a little tweak to reduce distance, but does work. The drawback is that the magnet picks up iron and steel swarf. Ok as a one off to check speed ranges, but an optical sensor might be a better option:

- Joined

- Apr 23, 2011

- Messages

- 2,477

Back before Christmas, I came across a decent quality 3 phase motor (Asea ) and decided to upgrade my Chester RF45 Mill, which I've owned and used for the last 5 years (https://www.hobby-machinist.com/threads/new-toy-s-h-rf45-mill.76666/). The original Chinese single phase motor (750W 1400rpm) motor was still working, but I was frustrated by the limited range and power through the gear box.

I took this motor off when I originally stripped the mill, but it was jammed on solidly when I came to remove it and I destroyed it in the process. Not quite sure how it had got stuck so fast, but there was some rust in the keyed input shaft union and I had to jack it off in stages..

The mill is shaft driven by a 3/4" shaft c/w 15/16" key. The motor mounts by a four hole bolt circle at 90 degrees, with 4 5/8" between centres and the motor has a 5 1/8" alignment ring.

View attachment 444012

This photo shows the different motor shafts and keys side by side, old motor armature to right

View attachment 444010

My new motor is an Asea MT90L24F165-4, which is a 1420RPM 1.5KW, which appears to have had a very light previous life in HVAC.

View attachment 444009

This motor has an identical bolt circle and alignment ring, but has a 15/16" shaft and was keyed to 5/16". This required a strip down, turning down and cutting a new keyway to match the input shaft on the mill. The turning was quick and easy on my Colchester lathe, but with no working mill I had to resort to using the lathe carriage as a manual shaper to cut the new keyway.

View attachment 444014

It took a little patience, but got there in the end:

View attachment 444015

All now ready to reassemble and mount - tbc in next post!