- Joined

- Dec 18, 2019

- Messages

- 7,407

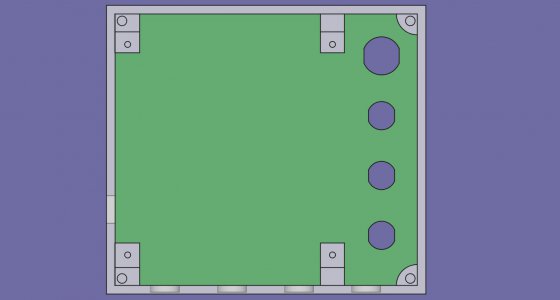

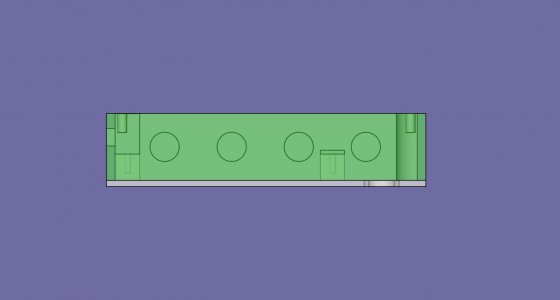

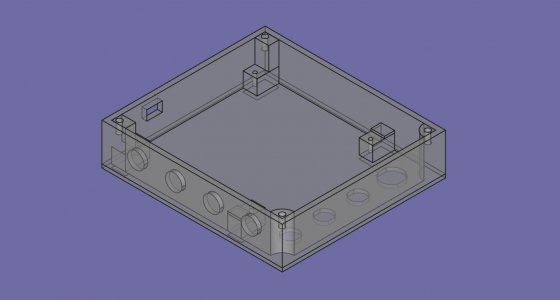

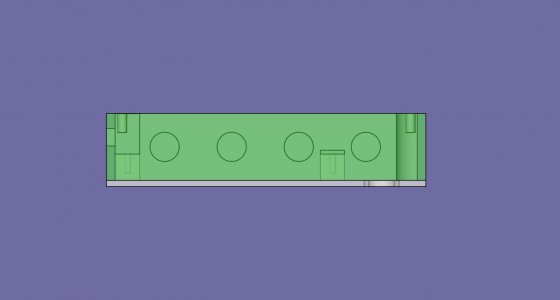

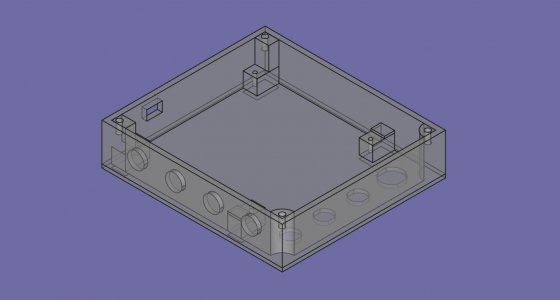

Since I started this thread, might as well ask here. I'd like to use some magnets to hold my ELS display box down to the lathe. My design now has 12.2mm diameter pockets for 12mm N52 magnets that are 2.8mm deep into the bottom wall of the box (really the side of the box). The magnets are allegedly 3mm thick. I was thinking of gluing them into the pockets and possibly putting a keeper steel plate across them inside the box. The magnets don't go through the box. The section under the magnet is 0.8mm, or 0.75mm depending on what layer thickness I use. (3 or four layers)

Is this sufficient? Is there another or better way to doing this?

Thanks for any insight on this. The four corner holes will have M3 brass inserts. I don't quite have enough room for inserts to hold the PCB down, without breakthrough. Can't lengthen them without running into a screw head on the PCB. If I redesign the PCB again, I'd fix that, but the PCB works, so there's little reason for a re-spin.

Is this sufficient? Is there another or better way to doing this?

Thanks for any insight on this. The four corner holes will have M3 brass inserts. I don't quite have enough room for inserts to hold the PCB down, without breakthrough. Can't lengthen them without running into a screw head on the PCB. If I redesign the PCB again, I'd fix that, but the PCB works, so there's little reason for a re-spin.