At the suggestion of another forum member I'm starting this thread here for more exposure. A few week ago I opened up this discussion on my PM-932 build there here - http://www.hobby-machinist.com/threads/taking-the-cnc-plunge.24858/. It starts on page 12, post #344.

Now to the issue at hand. A few months back I installed a 3ph motor and VFD to my CNC converted PM-932. This also included upgrading the stock tapered roller spindle bearings to angular contact bearings (ABEC 5 for the top bearing and ABEC 7 for the lower bearing). Then I followed up with new electronics: a PMDX-126 breakout board, a PMDX-107 spindle control board, and a ethernet smoothstepper. All these "improvements" are working well except that since then the surface finish on angular and circular cuts is terrible.

I've tried a multitude of Mach3 CV settings such as CV Distance Tolerance, bumped Look Ahead to 200 lines, made sure G100 Adaptive Nurbs CV was turned off, Shuttle Acceleration, changed speeds, feeds, cutter size, number of flutes, DOC, WOC, feed direction and spindle drive belt. Also made some changes to my CAM program but still no change in surface finish. Even went back and checked gib adjustment, twice. No improvement in surface finish. I'm at a loss as to what's causing this.

Any help is appreciated.

Here are a couple of pictures for reference.

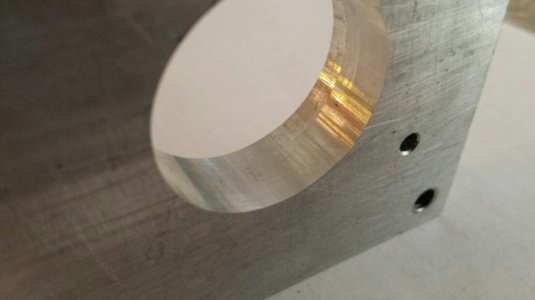

X and Y straight cuts give me a very smooth surface finish.

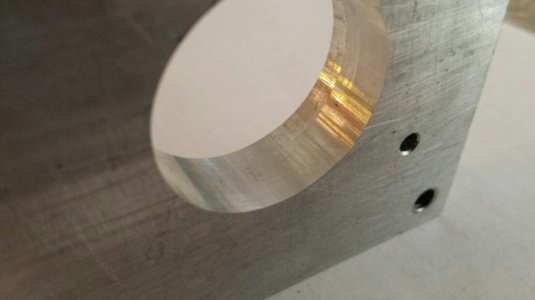

This is the surface finish I get with angular and circular cuts.

Now to the issue at hand. A few months back I installed a 3ph motor and VFD to my CNC converted PM-932. This also included upgrading the stock tapered roller spindle bearings to angular contact bearings (ABEC 5 for the top bearing and ABEC 7 for the lower bearing). Then I followed up with new electronics: a PMDX-126 breakout board, a PMDX-107 spindle control board, and a ethernet smoothstepper. All these "improvements" are working well except that since then the surface finish on angular and circular cuts is terrible.

I've tried a multitude of Mach3 CV settings such as CV Distance Tolerance, bumped Look Ahead to 200 lines, made sure G100 Adaptive Nurbs CV was turned off, Shuttle Acceleration, changed speeds, feeds, cutter size, number of flutes, DOC, WOC, feed direction and spindle drive belt. Also made some changes to my CAM program but still no change in surface finish. Even went back and checked gib adjustment, twice. No improvement in surface finish. I'm at a loss as to what's causing this.

Any help is appreciated.

Here are a couple of pictures for reference.

X and Y straight cuts give me a very smooth surface finish.

This is the surface finish I get with angular and circular cuts.