-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need Help Choosing My First Lathe

- Thread starter cngnow

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,634

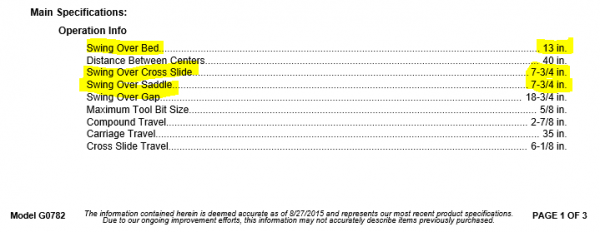

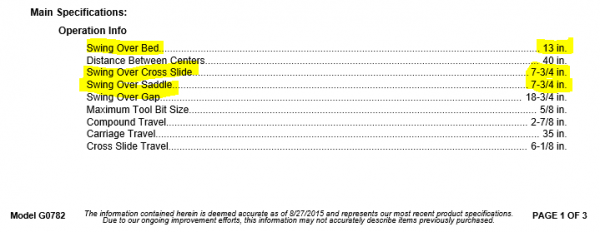

Look at the specs of the lathe for swing over the cross slide or saddle. Pic below is for a Grizzly G0782 13" swing lathe. I'm guessing you'll want at least an 11" or 12" swing lathe to comfortably turn a 5" round. As mentioned above, get the largest lathe your budget and space allow. You can turn small stuff on a large lathe but not the converse (without a pucker factor).

Bruce

Bruce

Wow, so much to consider. I was thinking about an oldlathe, but what if it needs a lot to get it into working order. Space is not an issue for me as I have an outbuilding with a room to fit a large lathe. I need to study and learn like jsh did. I guess bigger is always better when it comes to lathes.

I notice a lot of South Bend 9 and 10 lathes. What do you look for that makes them bad, besides obvious damage or missing parts?

I notice a lot of South Bend 9 and 10 lathes. What do you look for that makes them bad, besides obvious damage or missing parts?

- Joined

- Dec 6, 2012

- Messages

- 2,709

You might put out a request for a mentor in Maryland.

Somebody who would go lathe shopping with you or at least give you some hands on training on what to look for.

If you are like many of us the written word is great. But, hands on is better.

As for me, I'd go with old iron...

And yes, as per above, you can still get new parts for Logans (http://www.loganact.com/).

Daryl

MN

Somebody who would go lathe shopping with you or at least give you some hands on training on what to look for.

If you are like many of us the written word is great. But, hands on is better.

As for me, I'd go with old iron...

And yes, as per above, you can still get new parts for Logans (http://www.loganact.com/).

Daryl

MN

- Joined

- Sep 24, 2014

- Messages

- 929

I'm going to say it because nobody has yet. Get the biggest used lathe you can! If you can't turn a prop shaft for a super tanker it's not big enough!  My real advice would be to research, research, research. Then do what works for you. Everyone has an opinion, they are just like belly buttons, the only one that counts is yours.

My real advice would be to research, research, research. Then do what works for you. Everyone has an opinion, they are just like belly buttons, the only one that counts is yours.

- Joined

- Jul 10, 2013

- Messages

- 1,211

Are you mostly interested in making guns and rifles? Any lathe can just about do anything. But certain lathes can do certain jobs easier than other lathes. I'd check with gunsmiths and find out what they use. It seems to me that you want something with a big bore, rests, and spiders. A Grizzly g4003 comes to mind, in fact, they even call it a gun lathe. I don't work on guns but my brother-in-law does. He used an old Jet 10"(I don't recall what model).

If your considering buying used, this has lots of good info:http://www.mermac.com/advicenew.html

- Joined

- Aug 6, 2013

- Messages

- 336

I had a small grizzly mini lathe as my first lathe. I was able to learn on it but over time realized that it just wasn't large enough or just as importantly "rigid" enough to do some of the things I wanted. I looked for months for a good used lathe but the ones any where near me were either in very poor condition, way too old and beat up, or they were asking too much. As this is just a hobby for me (and I was tiring of searching for used, I decided to get a new G0602 and have been very pleased with it. My space is a bit limited so it fits well, but is large enough to accomplish anything I have needed it for (so far). More importantly it's a much heaver and solid machine than the mini mill was and the ease and quality of cuts is night and day. Now I'll admit, I still can't turn a prop shaft for a super tanker, but it fits my needs. It's not perfect, but there are lots of user mods and info on the net for small improvements. I also have a grizzly mill (converted to cnc now) and must say grizzly was very helpful with fixing and supplying parts etc, to remedy any issues or problems under warranty I've encountered with the machines no matter how minor.

- Joined

- Mar 29, 2014

- Messages

- 5

I bought a Grizzly G4002 years ago and am completely satisfied.

It has a geared head, relatively large bore and a 24 inch bed. I have a collet closer and collets. I use my collets and 4 jaw a lot. I rarely use a steady rest and have never used my traveling steady.

This is my third lathe, so I had the benefit of experience. I know that most of my work is held in collets or my 4 jaw and only occasionally machined between centers. I haven't needed a normal bed (36 inch or better) in decades

It has a geared head, relatively large bore and a 24 inch bed. I have a collet closer and collets. I use my collets and 4 jaw a lot. I rarely use a steady rest and have never used my traveling steady.

This is my third lathe, so I had the benefit of experience. I know that most of my work is held in collets or my 4 jaw and only occasionally machined between centers. I haven't needed a normal bed (36 inch or better) in decades

- Joined

- Dec 27, 2014

- Messages

- 658

I spent months agonizing over my first lathe. I finally went with an 11" Sieg model I got from DroPros. Not only did the lathe fail to perform well, and was way out of manufactures specs, DroPros screwed me over badly.

My advice to start with is: avoid Sieg (they make most of the 7x lathes), and avoid DroPros (they are wonderful until you have a problem then will boldly lie right to your face).

I still have the lathe, it is sitting in my garage on a palate taking up valuable space. You can have it for $1200.00 if you come through central Ohio to get it. The head stock is slightly out of alignment with the bed, probably an easy repair (probably). I paid $2k for it, will toss in the AXA tool post also. DroPros stopped carrying the model when I found the problems, they agreed that if I gave it to Matt at QMT, and he agreed it was out of factory spec, that they would give me full price off any lathe I purchased from Matt. They reneged on the deal as I was loading the lathe to take it to Matt, after I had already paid for my PM1340GT. They just flat out lied about making the deal - and they had the gal to do it in an email thread that actually included the deal.

I suggest you make a list of things it absolutely must have, a list of things it absolutely must not have, and a list of things you would like it to have.

For me,

It must have:

power carriage feed.

power cross feed (you do want this).

Threading dial (this means an Imperial lead screw on almost all lathes. Don't believe the lie, not having a half nut is the suck).

A repeatable spindle mount (This is probably something you also want given what you want to do).

A partial gear box (changing gears to change feed speeds is dumb).

Reversible spindle

Left hand threading (you prolly don't need this).

cross slide travel that is larger than 1/2 the swing (you would be amazed how many lathes don't)

It must not have:

screw on chuck (Screw on chucks are a deal breaker imo, this will include all the old and beloved SB's)

No way to attach a threading dial (they can be retrofitted on metric lathes)

I would like it to have:

variable speed

2" bore (that's pretty big for a small lathe).

coolant (still don't have this...)

All that said, one thing you do not want to be doing is running a piece of 5" stock on a 7" lathe. you prolly don't want to do this on a 9" lathe for that matter.

You should pay some extra attention to compound travel. You are intending to cut tapers on large stock, it is important that the compound has enough travel to cut those tapers.

I doubt you will find a lathe smaller than 10" that will spin a 5" part and cut a taper on it. it is not a deal breaker provided you can retrofit a taper attachment, once again, the lathe must be beefy enough to accommodate a solid taper attachment (prolly 10" minimum again).

Keep in mind that you will want the lathe to do other things at some point. As already advised, get the next size up from the biggest lathe you can afford (just find a way to afford it).

Many of us here own Precision Mathews machines, I have a lathe and a mill from PM. We buy his machines because he stands behind his products extremely well, and he works with the manufacturer to include things that a machine should have. He is experienced with machining, so he understands what a machinist wants. Call Matt and ask him what he suggests, he has a large inventory not on the website.

http://www.machinetoolonline.com/NewlatheIndex.html

My advice to start with is: avoid Sieg (they make most of the 7x lathes), and avoid DroPros (they are wonderful until you have a problem then will boldly lie right to your face).

I still have the lathe, it is sitting in my garage on a palate taking up valuable space. You can have it for $1200.00 if you come through central Ohio to get it. The head stock is slightly out of alignment with the bed, probably an easy repair (probably). I paid $2k for it, will toss in the AXA tool post also. DroPros stopped carrying the model when I found the problems, they agreed that if I gave it to Matt at QMT, and he agreed it was out of factory spec, that they would give me full price off any lathe I purchased from Matt. They reneged on the deal as I was loading the lathe to take it to Matt, after I had already paid for my PM1340GT. They just flat out lied about making the deal - and they had the gal to do it in an email thread that actually included the deal.

I suggest you make a list of things it absolutely must have, a list of things it absolutely must not have, and a list of things you would like it to have.

For me,

It must have:

power carriage feed.

power cross feed (you do want this).

Threading dial (this means an Imperial lead screw on almost all lathes. Don't believe the lie, not having a half nut is the suck).

A repeatable spindle mount (This is probably something you also want given what you want to do).

A partial gear box (changing gears to change feed speeds is dumb).

Reversible spindle

Left hand threading (you prolly don't need this).

cross slide travel that is larger than 1/2 the swing (you would be amazed how many lathes don't)

It must not have:

screw on chuck (Screw on chucks are a deal breaker imo, this will include all the old and beloved SB's)

No way to attach a threading dial (they can be retrofitted on metric lathes)

I would like it to have:

variable speed

2" bore (that's pretty big for a small lathe).

coolant (still don't have this...)

All that said, one thing you do not want to be doing is running a piece of 5" stock on a 7" lathe. you prolly don't want to do this on a 9" lathe for that matter.

You should pay some extra attention to compound travel. You are intending to cut tapers on large stock, it is important that the compound has enough travel to cut those tapers.

I doubt you will find a lathe smaller than 10" that will spin a 5" part and cut a taper on it. it is not a deal breaker provided you can retrofit a taper attachment, once again, the lathe must be beefy enough to accommodate a solid taper attachment (prolly 10" minimum again).

Keep in mind that you will want the lathe to do other things at some point. As already advised, get the next size up from the biggest lathe you can afford (just find a way to afford it).

Many of us here own Precision Mathews machines, I have a lathe and a mill from PM. We buy his machines because he stands behind his products extremely well, and he works with the manufacturer to include things that a machine should have. He is experienced with machining, so he understands what a machinist wants. Call Matt and ask him what he suggests, he has a large inventory not on the website.

http://www.machinetoolonline.com/NewlatheIndex.html