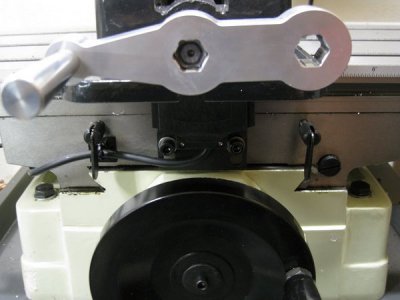

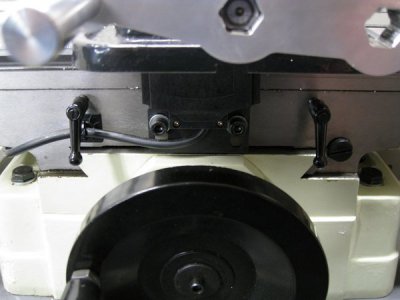

I picked some up that are the perfect size but aren't available in the size stud I need. So I also picked up some dog point set screws & went to work.

I'm very happy with them. I also inserted ball bearings into the holes before putting them on to prevent only one side of the dog point from contacting the gibs. If you shine a light down the holes you will see what I mean. Lock up feels so much better now.

If anyone is interested, these are the parts that I used:

Mcmaster:

[TABLE="class: OrdDtlTbl"]

[TR="class: OrdDtlRow"]

[TD="class: OrdDtlLnNbrCol"][/TD]

[TD="class: OrdDtlPartNbrCol"]

6848K12[/TD]

[TD="class: OrdDtlQtyCol"]6 Each[/TD]

[TD="class: OrdDtlDscCol"]Metric Die Cast Zinc Adjustable Handle, M6 X 1 Threaded Hole, 9mm Thread Depth[/TD]

[/TR]

[TR="class: OrdDtlRow MouseOverRowHighlight"]

[TD="class: OrdDtlLnNbrCol"][/TD]

[TD="class: OrdDtlPartNbrCol"]

92905A327[/TD]

[TD="class: OrdDtlQtyCol"]1 Pack[/TD]

[TD="class: OrdDtlDscCol"]Alloy Steel Extended Point Set Screw, M8 Size, 50mm Long, 1.25mm Pitch[/TD]

[/TR]

[/TABLE]

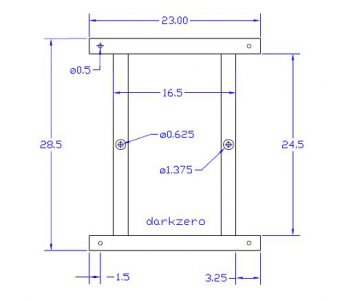

Shortened the set screws 6mm, threaded M6 x 1 thread 8.5mm long. I used 1/4" bearing quality hardened balls

(be sure to measure first, it will be a lot of work to get them out if they get stuck & I don't want to be the blame if it were to happen to someone, use 7/32" if you want to be safe). Since I used the balls to contact the gibs, dog point set screws weren't necessary, the idea came to me when I went to install the new handles.