-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My PM45M-PDF

- Joined

- Mar 22, 2013

- Messages

- 513

Hey Skeeter,

For the head gearbox lube, I have had a lot of guys using something like SAE75W90 gear oil, and they say it works well and runs quiet. The factory says #30 Machine Oil, which I have seen, and I think it is crude oil straight out of the ground. I use the 75W 90 in my own machine.

So really, that gear oil, or Mobil DTE, or any Hydraulic curculating / antiwear oil will be much better than what the factory would say to use.

For the ways or screws, any way oil, I have Tru Edge right now, or Mobil Vactra #2, or anything like that.

For the spindle splines, I would not worry too much about them, but something like white lithium grease would be good. And maybe a little way oil on the quill too, where it slides.

For that oil cap on top of the power down feed, I actually grease the gears inside of there, and do not oil them. But thats up to you, a little oil there won't hurt either.

And for that drawbar, I just screw it in by hand, and use the 2 nuts to tighten it, just hold the top one still and screw the nut down to pull the drawbar up. I do what Gary does sometimes too, but can't recommend doing that one, only can say that I do it too.

For the head gearbox lube, I have had a lot of guys using something like SAE75W90 gear oil, and they say it works well and runs quiet. The factory says #30 Machine Oil, which I have seen, and I think it is crude oil straight out of the ground. I use the 75W 90 in my own machine.

So really, that gear oil, or Mobil DTE, or any Hydraulic curculating / antiwear oil will be much better than what the factory would say to use.

For the ways or screws, any way oil, I have Tru Edge right now, or Mobil Vactra #2, or anything like that.

For the spindle splines, I would not worry too much about them, but something like white lithium grease would be good. And maybe a little way oil on the quill too, where it slides.

For that oil cap on top of the power down feed, I actually grease the gears inside of there, and do not oil them. But thats up to you, a little oil there won't hurt either.

And for that drawbar, I just screw it in by hand, and use the 2 nuts to tighten it, just hold the top one still and screw the nut down to pull the drawbar up. I do what Gary does sometimes too, but can't recommend doing that one, only can say that I do it too.

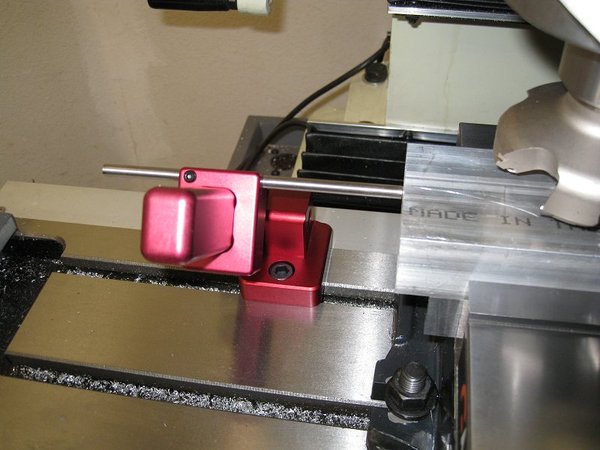

Their Pro Mill Stop. They have a few different vise stops but I decided to go with the table mount. This sucker is beefy as hell & works great!

The Pro Mill Stop is available with two different table slot widths - 5/8" and 9/16".

It looks like there is an integral boss at the base of the unit that fits into the table slot. Since the table slot width is 14 mm, did you get the 9/16" model and mill or shave down the edges to fit? 9/16" is 0.5625" while 14 mm is about 0.5512" so the difference is about 11 thousandths. Did it "just fit" as-is, or did you have to tweak it?

- Joined

- Nov 27, 2012

- Messages

- 7,970

The Pro Mill Stop is available with two different table slot widths - 5/8" and 9/16".

It looks like there is an integral boss at the base of the unit that fits into the table slot. Since the table slot width is 14 mm, did you get the 9/16" model and mill or shave down the edges to fit? 9/16" is 0.5625" while 14 mm is about 0.5512" so the difference is about 11 thousandths. Did it "just fit" as-is, or did you have to tweak it?

Yes, I got the 9/16" model & milled it down.

- Joined

- Nov 27, 2012

- Messages

- 7,970

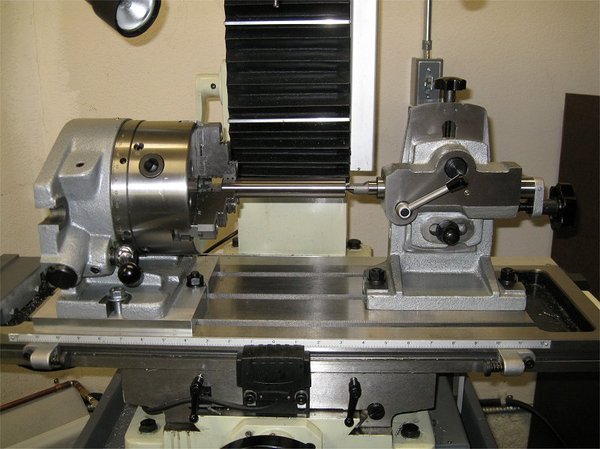

My 6" tail stock is almost maxed out in height so I decided to get a 8" tail stock as I wouldn't be able to use the 6" TS with the rotary table I will get later. I didn't want to make a riser for it. The 8" only costs $7 more than the 6" & both are well under $100 ea. I like the 8" better as it's facing "forward" but it's a bit bigger than the 6" so time will tell if I decide to sell the 6" or just keep it since it didn't cost much.

The 8" is nice cause it has a removable center but what is not mentioned anywhere I can find, there's no way of removing the center once it's seated good in the taper. So before I used it I took care of that by milling a slot for a drift key.

The 8" is nice cause it has a removable center but what is not mentioned anywhere I can find, there's no way of removing the center once it's seated good in the taper. So before I used it I took care of that by milling a slot for a drift key.

- Joined

- Nov 27, 2012

- Messages

- 7,970

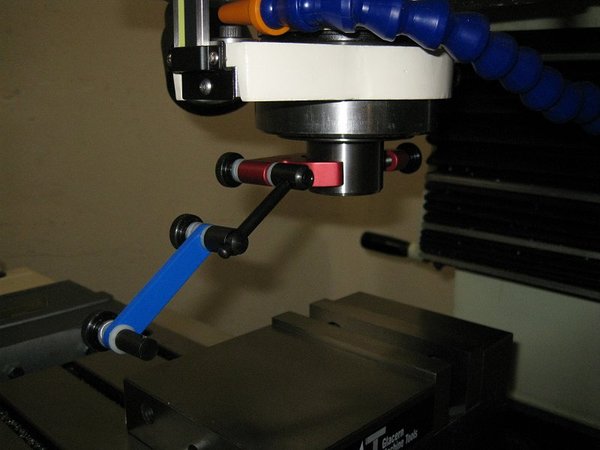

I had originally bought an Indicol but after using it one time I did not like it so I sold it.

I have a couple of Noga mag indicator holders which I love so I decided to get me a Noga for the spindle. I like this so much better!

As I posted earlier in this thread, I had previously bought an Indicol but I didn't like it so I sold it. The arms never really tightened up very firmly unless you really cranked down hard on the thumbscrews. Got the Noga, it's solid but there are times I wished I didn't have to remove the tool & swap in a collet to use it.

So I was watching a video someone posted by oxtools. In that video he had a Noga arm mounted on the Indicol base. Then I came across his video of it. A Noga and Indicol marriage. I thought that was a great idea so I decided to make me one too.

But I didn't buy another Indicol, this time I just bought an import clone for less than $10. Rather than drill & tap a hole on the mount like oxtools did I made an adapter. Like oxtools this time I'm using the Noga arm with fine adjust unlike my Noga that mounts in the collet. I really like this setup but I won't be putting my other Noga in retirement.

- Joined

- Nov 27, 2012

- Messages

- 7,970

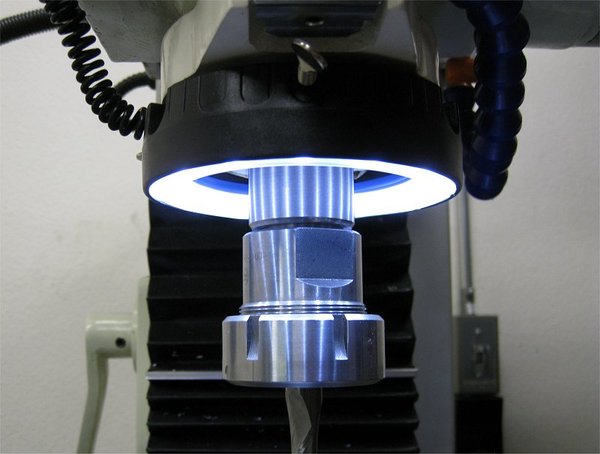

My spindle light......

I came across one of those drill press quill LED lights. Saw that Tormach was selling their own version which they had Nichia LEDs installed & for cheaper than what other vendors were selling the regular one for. They appeared to be just typical T1 LEDs though (I didn't open it up to verify the size), there are 14 of them. It worked as intended but coming from modding flashlights I just couldn't stand the very cool tint of the LEDs. I also didn't like how bulky it was as I couldn't use my spindle mount indicator holder with it very well. I did like the no tools required installation & magnetic switch with coil wire though.

So I returned that light & decided to build my own after seeing the angel eye/halo LED that xalky used for his mill. The vendor he linked didn't have the size I wanted so I ordered it on ebay. I used a 90mm ring with 60 LEDs.

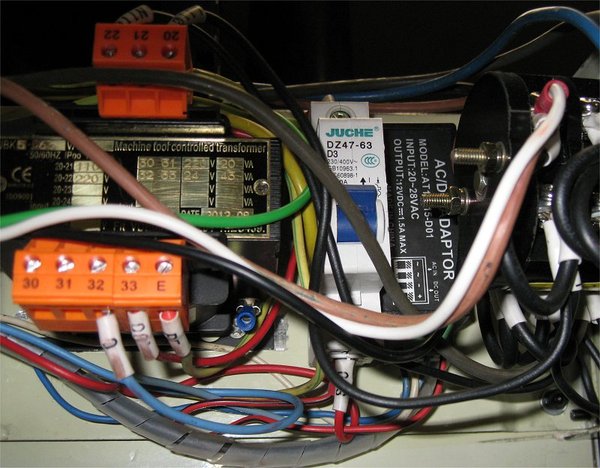

Here are the parts I used, the angel eye LED that I rewired, an AC to DC converter, & a lighted rocker switch.

I installed the AC to DC converter inside the control box which is being powered from the stock light's 24V circuit. It's connected to terminal 32 & the output of the white circuit breaker.

I choose the 90mm ring so it would fit just over the bottom ring on my quill. Had to remove just a bit of the ID to fit & it snaps right into place. Although I didn't need it I added a bit of double sided tape just in case. Couldn't have asked for a better fit!

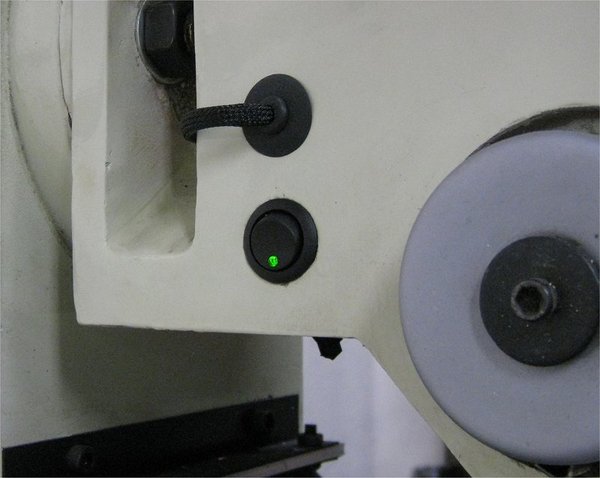

Installed the lighted rocker switch on one of the existing holes & the other hole for the wiring to the control box. I wonder what these two threaded holes are used for?

I'm very happy with this setup, very slim profile, & now I can still use my spindle mounted indicator holder. Thanks Marcel!

Thanks for looking.

I came across one of those drill press quill LED lights. Saw that Tormach was selling their own version which they had Nichia LEDs installed & for cheaper than what other vendors were selling the regular one for. They appeared to be just typical T1 LEDs though (I didn't open it up to verify the size), there are 14 of them. It worked as intended but coming from modding flashlights I just couldn't stand the very cool tint of the LEDs. I also didn't like how bulky it was as I couldn't use my spindle mount indicator holder with it very well. I did like the no tools required installation & magnetic switch with coil wire though.

So I returned that light & decided to build my own after seeing the angel eye/halo LED that xalky used for his mill. The vendor he linked didn't have the size I wanted so I ordered it on ebay. I used a 90mm ring with 60 LEDs.

Here are the parts I used, the angel eye LED that I rewired, an AC to DC converter, & a lighted rocker switch.

I installed the AC to DC converter inside the control box which is being powered from the stock light's 24V circuit. It's connected to terminal 32 & the output of the white circuit breaker.

I choose the 90mm ring so it would fit just over the bottom ring on my quill. Had to remove just a bit of the ID to fit & it snaps right into place. Although I didn't need it I added a bit of double sided tape just in case. Couldn't have asked for a better fit!

Installed the lighted rocker switch on one of the existing holes & the other hole for the wiring to the control box. I wonder what these two threaded holes are used for?

I'm very happy with this setup, very slim profile, & now I can still use my spindle mounted indicator holder. Thanks Marcel!

Thanks for looking.

- Joined

- Dec 18, 2013

- Messages

- 2,690

Very nice, quality install. Do you have a pic of the table with the light on vs off? I find anymore I need my work lit up like the sun to see. Also how much an hour to hire you to teach me how to weld like that stand in the first post wow! I picked up a used USA Hobart Mig recently and plan to fabricate a new stand for my lathe once the weather gets nice and I can do that project outside. The factory stand is about 5 inches too high for me.

- Joined

- Nov 27, 2012

- Messages

- 7,970

Very nice, quality install. Do you have a pic of the table with the light on vs off? I find anymore I need my work lit up like the sun to see. Also how much an hour to hire you to teach me how to weld like that stand in the first post wow! I picked up a used USA Hobart Mig recently and plan to fabricate a new stand for my lathe once the weather gets nice and I can do that project outside. The factory stand is about 5 inches too high for me.

Thanks! I'll be out tomorrow so I'll snap a pic if I get back in early enough or Sunday. Originally I was worried about it being too bright & was going to use a SPDT switch for dual brightness but I realized when I was test lighting the ring I had it running at 14V. It's not too bright, I was concerned about being too bright & glare. I mainly wanted this for when I use my super spacer since I use it on the left side of the table & the stock halogen light is on the left so it's hard to see what I'm working on sometimes.

LOL, I wish I could weld like that too. The last time I welded was 10 years ago with a mig building a gate & I didn't know what I was doing. I first tried to mig the stand by myself with a welder I borrowed from a friend. That didn't turn out well & I didn't trust the mill on a stand I welded. So I just tacked it & took it to a local shop. Cost me $50, I was expecting to grind down the welds after I got it back but to my surprise they tig welded it. So....how much an hour for you to teach me how to weld? :lmao:

- Joined

- Dec 18, 2013

- Messages

- 2,690

Thanks! I'll be out tomorrow so I'll snap a pic if I get back in early enough or Sunday. Originally I was worried about it being too bright & was going to use a SPDT switch for dual brightness but I realized when I was test lighting the ring I had it running at 14V. It's not too bright, I was concerned about being too bright & glare. I mainly wanted this for when I use my super spacer since I use it on the left side of the table & the stock halogen light is on the left so it's hard to see what I'm working on sometimes.

LOL, I wish I could weld like that too. The last time I welded was 10 years ago with a mig building a gate & I didn't know what I was doing. I first tried to mig the stand by myself with a welder I borrowed from a friend. That didn't turn out well & I didn't trust the mill on a stand I welded. So I just tacked it & took it to a local shop. Cost me $50, I was expecting to grind down the welds after I got it back but to my surprise they tig welded it. So....how much an hour for you to teach me how to weld? :lmao:

Damn it I thought I was going to get some expert welding tips, wait I believe I saw the appropriate emoticon...:yousuck2:lol Plus your avatar continues to give me lathe chuck drool. Thanks for the pic I'll check back on that. It was a real nice install it looks factory.