-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My homemade bar puller for my CNC lathe.

- Thread starter rgray

- Start date

- Joined

- Nov 26, 2012

- Messages

- 1,307

Here is the second side machining of the tap holder from the first video.

I ran all these last weekend, but saved 3 for the video. I was waiting for that waterproof GoPro housing. It came in and I made a video and it was

terrible. The coolant was spraying the camera so bad you couldn't see much.

So I changed the camera location to the opposite end of the cabinet and it is better.

I ran all these last weekend, but saved 3 for the video. I was waiting for that waterproof GoPro housing. It came in and I made a video and it was

terrible. The coolant was spraying the camera so bad you couldn't see much.

So I changed the camera location to the opposite end of the cabinet and it is better.

- Joined

- Nov 26, 2012

- Messages

- 1,307

I just had another thought, try issuing a G98 (inches/min) after the G5. This might allow the X and Z to move when the spindle is stopped. Then issue a G99 (feed/rev) again after the bar pull.

So I reloaded the program and put some G98 & G99s in and all works great once I figured out where to put them.

Like the speed commands when I was lacking them to make my turret move I've probably entered more than I need.

Now that it works I'll have to delete some and see what is actually needed.

I got some alarm codes I'd never seen before.

One odd thing I can't figure out is the lathe will run the program through and reset so all I need to do is push cycle start to run another part.

This is same as was before.

But the second time you push cycle start it proceeds as normal till the first tool I'm calling on turret 2 (spot drill) G1 X0. Z-.07 F.004; the lathe puts the tool in place and them stops and turret 2 has a 011 alarm (the feed rate was not specified for cutting feed or the feed rate was inadequate)

Originally I had the feed at .002 changing this number makes no difference as far as I can tell.

This makes no sense to me as it does not alarm on the first run.

Hitting the E-stop and then shutting down the display power and then rehoming will make it proceed into spot drilling with the tool offset missing.

Another E-stop as it tries to spot drill the side of the part.

Shutting completely down and restarting makes it work perfect for another part and then same thing.

Any ideas?

- Joined

- Nov 26, 2012

- Messages

- 1,307

Maybe add a G99 after (before?) the tool change

That was it. Thanks so much for the help. I actually struggled with that when setting up the bar pulls. After the first pull is the cutoff and the tool would advance and stop at the no-turning rod and I had to add the G99 to cancel the G98 so the spindle could run and make the cut off.

What I didn't do was cancel the G98 from the second bar pull.

What is odd to me is how it would machine the first feature (turret 1) switch to turret 2 advance the turret to the work and then alarm and stop.

If G98 was active the spindle should not have turned for the first feature.

Oh well works great now. This machine is smarter than I am. Tells me what is wrong and all. Gives clues anyway (feed rate wrong) yep spindle not turning feed rate is wrong.LOL

Did an updated video. Moved the camera to the back cause the coolant spray was so bad where it was. Unfortunately that makes it harder to see the bar pulling/collet action. There is a light in the way so to get the needed height I moved the camera right and up. To see the bar pulling better I should have moved left of the light.

- Joined

- Jan 31, 2016

- Messages

- 12,901

Russ , just got your message . Does your number start with 406 ? Your number didn't come thru but you can give me a yell anytime tonight , I'm here at work till 7am my time . Dave .

- Joined

- Nov 26, 2012

- Messages

- 1,307

I needed to run some brass bushings and being spoiled by the 1" bar puller I just had to make another.

5/8" this time. I made it from a truck leaf spring so it is spring steel. it's way to heavy to be very springy but works great anyway.

if I make more sizes I will remove more material so they might actually spring.

Here's my raw material.

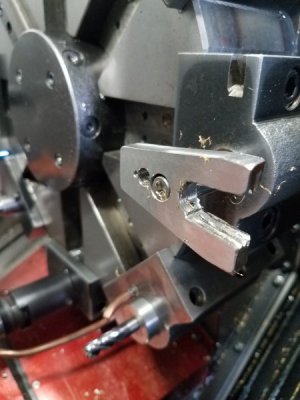

And here it is on the lathe. My intention was to pin and dowel it to the shaft. I did that but when the turret rotates it ran into the

way covers. I had to redrill a hole to shorten its reach. I didn't bother with the dowel hole the second time, there wasn't room for it between the two holes.

It is bolted to an unhardened piece of O-1 drill rod.

And a video of it in action.

Even turned the coolant off. Figured I could get away with that on brass for 1 bushing.

5/8" this time. I made it from a truck leaf spring so it is spring steel. it's way to heavy to be very springy but works great anyway.

if I make more sizes I will remove more material so they might actually spring.

Here's my raw material.

And here it is on the lathe. My intention was to pin and dowel it to the shaft. I did that but when the turret rotates it ran into the

way covers. I had to redrill a hole to shorten its reach. I didn't bother with the dowel hole the second time, there wasn't room for it between the two holes.

It is bolted to an unhardened piece of O-1 drill rod.

And a video of it in action.

Even turned the coolant off. Figured I could get away with that on brass for 1 bushing.

- Joined

- Nov 26, 2012

- Messages

- 1,307

Made another bar puller. This time a 1/2" and 3/8" double ended puller.

Worked great but gripped a 1/2" rod to deep in it's throat for my latest project.

So I built another that is extended out farther and grips the bar closer to the end (of the puller) so my latest

project had clearance to clear the tool holder. Here it is installed.

Works great here's a vid of it working.

These are handles with a 5/16-18 thread. 4130 and here's a pic of them after heat treat and temper.

Worked great but gripped a 1/2" rod to deep in it's throat for my latest project.

So I built another that is extended out farther and grips the bar closer to the end (of the puller) so my latest

project had clearance to clear the tool holder. Here it is installed.

Works great here's a vid of it working.

These are handles with a 5/16-18 thread. 4130 and here's a pic of them after heat treat and temper.

- Joined

- Nov 26, 2012

- Messages

- 1,307

So I got some W1 and was running a few more of those handles tonight, tweaking offsetts, sharpening carbides, changing feed rates, and all that fun stuff.

Had things working good, but I was still messing with offset on the threading tool. The thread was just a little loose and I figured I'd tighten it up a little. Actually I was changing the value of the cut ....not the offset, and forward slashing / the original figures so I could run the new numbers and have the machine ignore the originals by switching on "block delete".

So I was watching this particular handle and the program was at the knurling part, and I hear a clunk like something fell down into the chip conveyor.

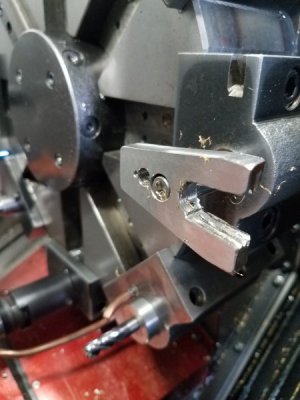

It finishes knurling, cutting off, and pulling the bar. and I find this.

I haven't been very good about stopping before the stock runs out. and so the collet is closed on nothing every time I use up a bar.

I've been running 3' and 4' bars.

I had decided I would get better at that and I knew I could only get 5 handles out of the 3' bars I was running.

But I guess that was a little to late. My abused collet gave up on me.

Had things working good, but I was still messing with offset on the threading tool. The thread was just a little loose and I figured I'd tighten it up a little. Actually I was changing the value of the cut ....not the offset, and forward slashing / the original figures so I could run the new numbers and have the machine ignore the originals by switching on "block delete".

So I was watching this particular handle and the program was at the knurling part, and I hear a clunk like something fell down into the chip conveyor.

It finishes knurling, cutting off, and pulling the bar. and I find this.

I haven't been very good about stopping before the stock runs out. and so the collet is closed on nothing every time I use up a bar.

I've been running 3' and 4' bars.

I had decided I would get better at that and I knew I could only get 5 handles out of the 3' bars I was running.

But I guess that was a little to late. My abused collet gave up on me.