- Joined

- Aug 6, 2015

- Messages

- 4,298

Back... turns out this wood lathe was 10 minutes from the house in Ocala... so leaving it here instead of taking it with me to Orlando...

Of course it was pouring when I went to pick it up... wrapped as much as I could with a tarp and headed home... Sprayed some WD-40 followed with a wipe and then some way oil everywhere...

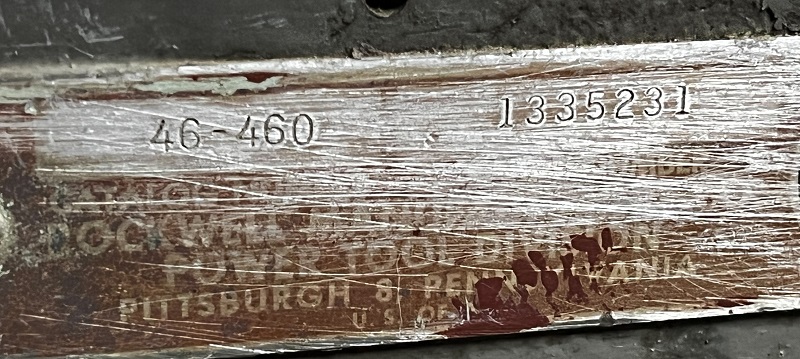

I did not grasp, from the photos, the width of the table. It is not that wide at all... Turns out this was from the grandfather of the seller... I am thinking this lathe is from around the 1960's... will check in the other forum to see if I can decipher the serial number...

Not really sure what to do... I just need a solid base for my 9x20... this wood lathe is a great candidate for me to restore... even if I do not work anything with wood...

Back to normal programming... taking a few work related calls before I head back to Orlando.

Of course it was pouring when I went to pick it up... wrapped as much as I could with a tarp and headed home... Sprayed some WD-40 followed with a wipe and then some way oil everywhere...

I did not grasp, from the photos, the width of the table. It is not that wide at all... Turns out this was from the grandfather of the seller... I am thinking this lathe is from around the 1960's... will check in the other forum to see if I can decipher the serial number...

Not really sure what to do... I just need a solid base for my 9x20... this wood lathe is a great candidate for me to restore... even if I do not work anything with wood...

Back to normal programming... taking a few work related calls before I head back to Orlando.