-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Monarch 10EE rebuild 10Hp VFD no backgear

- Thread starter Karl_T

- Start date

- Joined

- Apr 10, 2021

- Messages

- 617

The WJ200 is what I have too. I had all the programming instructions for a lathe conversion from Mark Jacobs so I took the easy route. Dave

- Joined

- Oct 14, 2014

- Messages

- 2,112

WOOHOO - the VFD is in and comes on!

Got Estop wired and working, coolant pump wired and working. VFD comes on.

VFD wants to run at 0 speed, got to figure how to change that from panel. Not like all other VFDs I have used where there is a little pot. want to get it running with defaults first.

There is a large WARNING tape over the brake and reactor connections. Want to double check what contacts these wire to.

guess its time to start reading the manual. programming these is something I seldom do.

Got Estop wired and working, coolant pump wired and working. VFD comes on.

VFD wants to run at 0 speed, got to figure how to change that from panel. Not like all other VFDs I have used where there is a little pot. want to get it running with defaults first.

There is a large WARNING tape over the brake and reactor connections. Want to double check what contacts these wire to.

guess its time to start reading the manual. programming these is something I seldom do.

Attachments

- Joined

- Oct 14, 2014

- Messages

- 2,112

Hmm... Not seeing how to run it different speeds from keypad. Must be buried in the manual someplace.

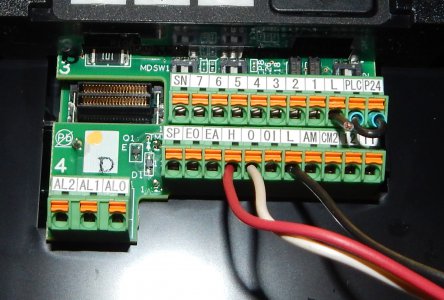

So, looked up wiring pot. looks like pot ground goes to L terminal

pot reference goes to H terminal

pot slider goes to O terminal

see pic.

Might as well do forward off reverse

contact power to P24 terminal

Forwad contact to 1 terminal

Reverse contact to 2 terminal

i will have to look up programming to make these work

Also found brake resistor goes to P/+ and RB terminals

DC reator goes to PD/+1 and P/+ terminals

(I am going to use this forum to keep my notes on this part of the job in case i have to re do this again later)

So, looked up wiring pot. looks like pot ground goes to L terminal

pot reference goes to H terminal

pot slider goes to O terminal

see pic.

Might as well do forward off reverse

contact power to P24 terminal

Forwad contact to 1 terminal

Reverse contact to 2 terminal

i will have to look up programming to make these work

Also found brake resistor goes to P/+ and RB terminals

DC reator goes to PD/+1 and P/+ terminals

(I am going to use this forum to keep my notes on this part of the job in case i have to re do this again later)

Attachments

- Joined

- Jun 12, 2014

- Messages

- 5,056

You might look at the attached document for some programming options. Instead of the contactors you are using a maintained switch for the run commands. You want to have the USP active all the time to prevent the machine restarting if it powers down with it in a run command mode or consider using some relays for run commands. There is also the issue if you engage the E-Stop and you have an active run command, the machine will restart. Typically there is a power relay which is latched in the stop spindle position only and drops out with power loss or E-Stop engagement. With the WJ200 there is a simple single relay design that I used many years ago with this type of latching system if you are interested.

Mark

Mark

Attachments

- Joined

- Oct 14, 2014

- Messages

- 2,112

What an AWSUM write up. I have read through it twice and will do a third time before programming.

Now, i do not make bulk changes. get something wrong, it don't work right and you don't know what is wrong.

OK if I attach the pot and change A001 to 1, should the machine run??

Then I will attach the forward reverse to terminals 1 and 2 and change A002 to 01.

Then start working my way through stopping to test frequently.

Now, i do not make bulk changes. get something wrong, it don't work right and you don't know what is wrong.

OK if I attach the pot and change A001 to 1, should the machine run??

Then I will attach the forward reverse to terminals 1 and 2 and change A002 to 01.

Then start working my way through stopping to test frequently.

- Joined

- Oct 14, 2014

- Messages

- 2,112

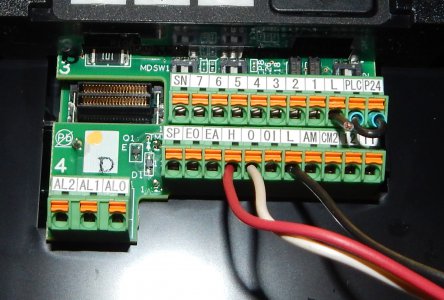

OK, question of the moment. The logic connectors are just push the wire in, spring locked in place. How the heck do you release them? made a mistake on the wrong L terminal. Also have to remove the P24-PLC jumper. I tried pushing on the orange part, no joy and I was going to break something.

Close up pic of terminals:

Close up pic of terminals:

- Joined

- Jun 12, 2014

- Messages

- 5,056

- Joined

- Oct 14, 2014

- Messages

- 2,112

Thanks, only takes a second when you know how. In looking over the manual for this issue, i came across wiring the inputs sinking. So, I just put common on L, forward on 1 and reverse on 2. it works. Any reason to change to sourcing like you show?

MAN DID YOU EVER SAVE ME TIME AND FRUSTRATION!!! Went clear through your cheat sheet and machine runs GREAT!

Also played with the Estop leaving the machine in forward. Hit Estop then reset - machine will not turn. Turn power off with lever in forward then re apply power - machine will not turn. These two trials really the same thing as Estop kills power to VFD. BTW, i had never seen that option to have braking with power off - MAN is that nice. Anyway, I am not seeing a need to add a latching relay on the forward/ reverse switch. Am I missing something? Another relay is no big deal.

One little thing I'd like to change, machine will go clear to 0 speed with pot all the way down. There must be a parameter for min speed? Did not see it on quick pass through listing. maybe one for min frequency? Or do i need to add a resistor?

Other thing I'd like to look at. this is a tool room lathe NOT a big beefy hogging machine. I went with 10 Hp only to get torque at very low frequency. I'd like machine to kick out if some idiot tries a huge deep cut at high feed. Any way to limit amps and not hurt low end torque?

I want to THANK EVERYONE AGAIN FOR THE GREAT HELP. I also ran this build thread over on practical machinst because that's where the expertise is on the 10EE. All I got was crap and derision.

MAN DID YOU EVER SAVE ME TIME AND FRUSTRATION!!! Went clear through your cheat sheet and machine runs GREAT!

Also played with the Estop leaving the machine in forward. Hit Estop then reset - machine will not turn. Turn power off with lever in forward then re apply power - machine will not turn. These two trials really the same thing as Estop kills power to VFD. BTW, i had never seen that option to have braking with power off - MAN is that nice. Anyway, I am not seeing a need to add a latching relay on the forward/ reverse switch. Am I missing something? Another relay is no big deal.

One little thing I'd like to change, machine will go clear to 0 speed with pot all the way down. There must be a parameter for min speed? Did not see it on quick pass through listing. maybe one for min frequency? Or do i need to add a resistor?

Other thing I'd like to look at. this is a tool room lathe NOT a big beefy hogging machine. I went with 10 Hp only to get torque at very low frequency. I'd like machine to kick out if some idiot tries a huge deep cut at high feed. Any way to limit amps and not hurt low end torque?

I want to THANK EVERYONE AGAIN FOR THE GREAT HELP. I also ran this build thread over on practical machinst because that's where the expertise is on the 10EE. All I got was crap and derision.

- Joined

- Jan 26, 2012

- Messages

- 87

Karl, the other two wires on the rotary F/C/R switch are for neutral safety. You wire them so you can't energize with the rotary switch in either F or R. Bill<snip> Found the three wires for the forward/off/reverse lever and labeled them F C R for forward common reverse. EXTRA CREDIT - I could not remove the plate shown in the pic. It was still tight after removing the four slot head screws. Beating on it with a chisel etc. was no help. HOW to do it?? Also there are five conductors here, what could the other two be for? <snip>