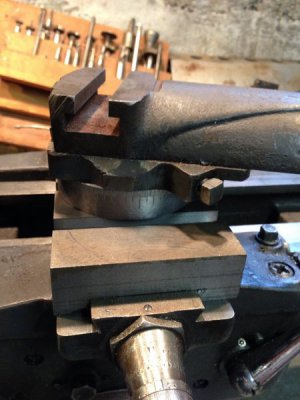

Rob,

I know that the photos are just to show how you mounted the pintle and compound swivel. But when you cock the compound aroud to 30 degrees, you should normally realign the QCTP square with the lathe's spindle axis. The way that I do it is to temporarily mount a piece of solid round (I use a precision ground test bar that I have) in the chuck, slack the TP pinch bolt or nut, and advance the compound until the flat face of the TP is flat against the round bar, and tighten the bolt or nut. With a Wedge type TP, you may have to put a #101 or 102 tool holder on the TP to register against the bar.