Thanks!Nicely finished. Nice score on the DRO too. I took a spin back through the thread which prompted a few questions for you.

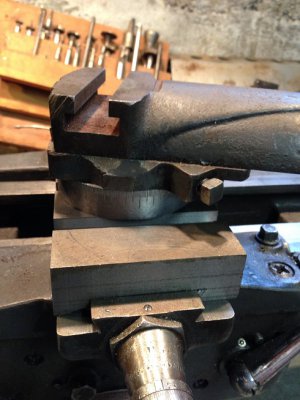

The slots are 5/8" wide in the "T" and 3/8" in the slot, and take standard size T-nuts for 5/16"-18 fasteners.

- What are the T-Slot dimensions?

Yes exactly. Still need to make a lever for it, or just run a pin through the head of it, so it can be used without tools.

- I notice one gib screw backed off in the picture. Is there going to be a lock?

Yes you could do it from the side, but I was tool blocked by the DRO scale, and decided to do it from above. I didn't permanently install them until after the grind. They are just a snug slip fit, and held in with some sleeve retaining compound.

- Would there be a way to install the oilers somewhere other than the machine surface? With cross drilled passages maybe? I presume they were installed low enough they were non-issues for the surface grind.

Didn't have much choice on it. Basically located exactly where the factory nut was, relative to the screw support bushing in the carriage. The screw is then drilled through(as is the nut), and when I make the cover/plug, it will have a ball oiler in it as well, so the nut can be oiled easily.

- Curious about the mounting provisions for the lead screw nut. Full travel dictates location so not many (good) choices about mounting through the machine surface there but can you elaborate on this feature.

Good questions!

Best,

Kelly

Last edited: