- Joined

- Mar 5, 2023

- Messages

- 97

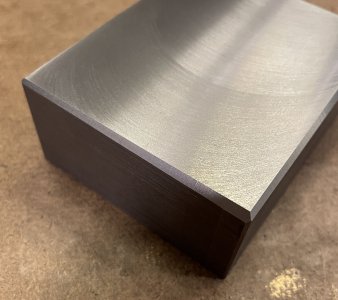

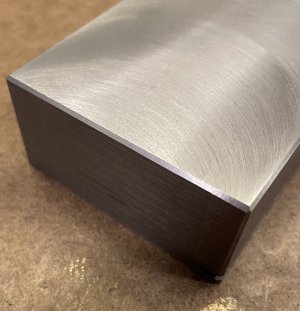

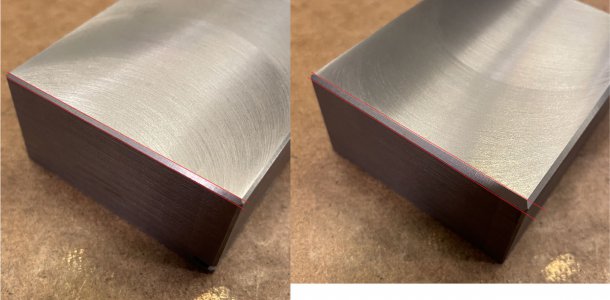

So I have the LMS 3990 mini mill and I've been using it for about a year now. I trammed it as a novice but felt like I had it pretty dialed in. Putting the finishing touches on this solid block of cast iron that I'll be using as a solid tool post with a 3/8 chamfer end mill bit. I did one side using the y-axis as my feed, kept the part in the vice and moved the spindle to the other side to finish both edges. One side looks really good but the other side is off by a noticeable amount. Thankfully this is merely cosmetic, but I'd like to correct. Seems odd that moving 2" on the x axis to do the other side would have it off by this much. Was there something else that could have caused this?

Pics below of both edges.

Pics below of both edges.