- Joined

- Dec 18, 2019

- Messages

- 7,424

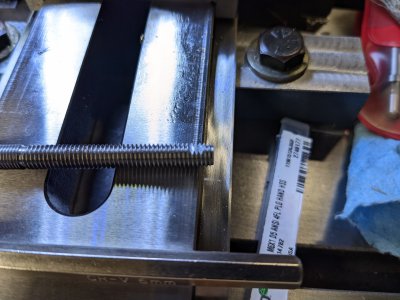

Back to this. Today decided to finish the longer screw. Did not use the follow rest, but really should have. Just too much deflection when threading.

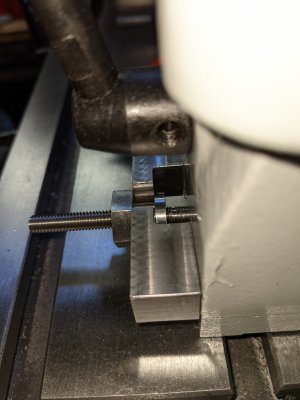

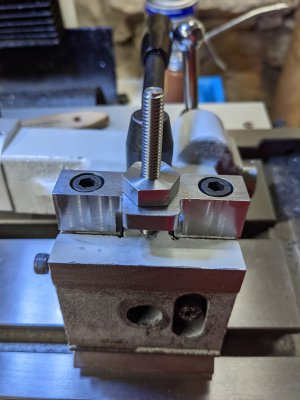

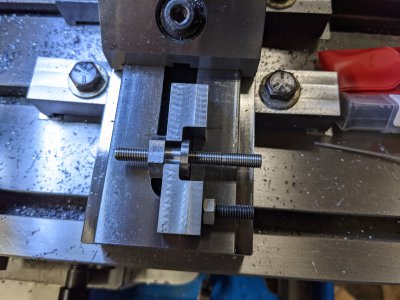

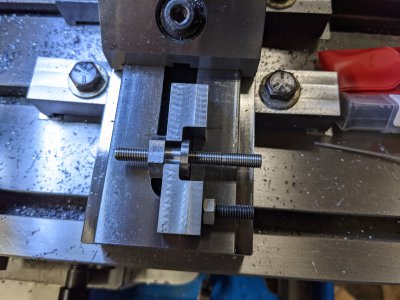

You can see the threads are ok nearer the chuck, but not deep enough far away. I measured the threads near the chuck using the 1 wire method and found them to be on the high side of nominal. I decided to part off the piece and finish the rest of the threads with a die. As it turns out, the die just barely cut metal, so it was pretty close. Here's a shot of the new screw with nut and bracket.

Tomorrow we figure out how to drill the tailstock and install everything.

You can see the threads are ok nearer the chuck, but not deep enough far away. I measured the threads near the chuck using the 1 wire method and found them to be on the high side of nominal. I decided to part off the piece and finish the rest of the threads with a die. As it turns out, the die just barely cut metal, so it was pretty close. Here's a shot of the new screw with nut and bracket.

Tomorrow we figure out how to drill the tailstock and install everything.