I hope I'm posting in the right place, but I have a question about my mini lathe. If anyone has seen this youtube channel "Adventures with a very Small Lathe" I have the same type of lathe the only difference is mine is 14 inches, his is the 12 inch version. I'm have the same problems that he is, his lastest video is about the saddle, here is a link

. My question, can you shim a moving part? In his video you can see that the saddle is not flat, he uses some gauge blocks to lift the flat side of the saddle to get it about even, to add some more context to my question to fix this problem that me and him are having could you drill and tap some holes to affix a shim plate to the saddle( I'm a beginner I don't know if this is a very bad idea ) or would you have to remachine the V notch to make it deeper? Or would I be better off just ordering a new saddle from Little Machine Shop? Thanks, I was surprised by how quickly and helpful the people are on this forum, thanks again.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mini lathe shimming

- Thread starter maddthom

- Start date

- Joined

- Apr 30, 2015

- Messages

- 12,254

Did you just recently purchase this machine? If so I would consider this type of defect to be good reason to consider returning the machine. Talk to your credit card company. Normally, shimming sliding parts is not a great approach, but is sometimes done in a pinch on older, really worn equipment. Should not be required on a new machine though

-Mrk

-Mrk

- Joined

- Dec 20, 2012

- Messages

- 9,422

Given that you cannot return it and also given that shimming the rear is not a good fix, have you considered milling the front V to the proper dimensions on both the headstock and the saddle? A lathe with these defects is not going to be very accurate at all until you fix it.

- Joined

- Jun 7, 2013

- Messages

- 10,452

Before proceeding with such a "fix" I would make sure that the alignment with the lead screw and rack gear are considered. If those dimensions are correct, then shimming at the back is the way to proceed; It might be well to machine the back surface deeper so that the shim can be thicker so that it could be secured with flat head screws, then scraped to fit the bed. Another matter is the respective center heights of the head and tailstocks, it is important that they be quite close to the same height after refitting.Given that you cannot return it and also given that shimming the rear is not a good fix, have you considered milling the front V to the proper dimensions on both the headstock and the saddle? A lathe with these defects is not going to be very accurate at all until you fix it.

- Joined

- Dec 11, 2013

- Messages

- 302

I would think that if the Tailstock is in alignment with the Headstock and spindle, that it can be left alone with no changes.

It is the Saddle where, as the compound is advanced that it is NOT in a parallel plain to the bed and will cause the cutting edge to be off the center line of the work (moving down) as the tool moves inward.

Atlas Lathes had shims on the saddle. although they were NOT made to correct a height issue they are used to compensate for wear with the flat ways.

I would agree that you should be able to make a Brass Shim Plate for the full length of the saddle out of Brass Flat Stock and secure it with countersunk flat head machine screws.

This Main Height Shim would need to be scrapped in and made flat and over time it may need to be replaced for wear.

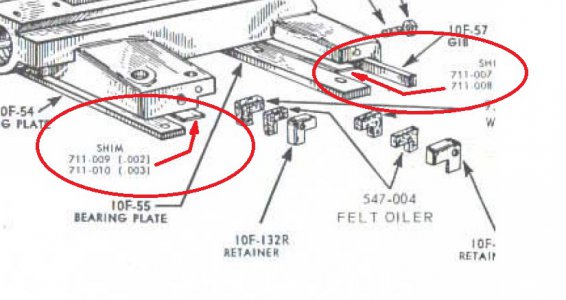

Additional minor height adjustments could be made using shim stock (available in increments of .001 thru .005, etc.) and placed between this part and the saddle as was done on the atlas lathe saddles between the saddle and the bearing plate, see attached pic.

You may want to look at the Atlas Parts diagrams in the library on the site.

It is the Saddle where, as the compound is advanced that it is NOT in a parallel plain to the bed and will cause the cutting edge to be off the center line of the work (moving down) as the tool moves inward.

Atlas Lathes had shims on the saddle. although they were NOT made to correct a height issue they are used to compensate for wear with the flat ways.

I would agree that you should be able to make a Brass Shim Plate for the full length of the saddle out of Brass Flat Stock and secure it with countersunk flat head machine screws.

This Main Height Shim would need to be scrapped in and made flat and over time it may need to be replaced for wear.

Additional minor height adjustments could be made using shim stock (available in increments of .001 thru .005, etc.) and placed between this part and the saddle as was done on the atlas lathe saddles between the saddle and the bearing plate, see attached pic.

You may want to look at the Atlas Parts diagrams in the library on the site.

Attachments

Dude, thanks I have zero experince with any other lathe, I did not know if shimming a moving or sliding parts was possible or a very bad idea. I have some brass flat bar I got it so that I could replace the gibs and flat bars that hold the saddle to the table, just a rough measurement it is about .95mm lower. But, is a shim with a thickness of about 1mm thick enough to counter sink some screws? Or would locktight be strong enough to hold it? Or would I have to machine the saddle so that I could use a shim thick enough to be held in place by some counter sunk screws? If you watch this guy's Youtube channel the head stock has the same problem, I would assume that tilt is shifting the headstock over, is that correct I haven't measured it yet.

- Joined

- Sep 5, 2013

- Messages

- 3,798

Yep that’s pretty thin for screws. If you have clear access on either side of the saddle you may get away with just bending up the ends of the shim strip to capture it in place. At the very least it’s an easily reversible trial method before gluing something in position. Just a thought, I’m not real familiar with the nuances of the particular machine.is a shim with a thickness of about 1mm thick enough to counter sink some screws?

-frank

- Joined

- Jul 28, 2017

- Messages

- 2,565

If the tailstock, saddle AND headstock all have the same problem that points toward the lathe bed -- it's common to all three. It's hard to believe that all 3 were that badly made. Or perhaps you have a frankenlathe, put together out of spare parts from where-ever. Do you know anyone in your area who has a similar machine? You could see if the tailstock and saddle fit OK on that one. If so, it might be most expedient to just replace the bed. LMS has 7x12 beds for a little under $145 (not counting shipping). Another (and less expensive) source would be Grizzly, about $84 -- but they are out of stock at the moment.

For a bit more you could step up to a 7x14 or 7x16, but would likely need to come up with your own motor mounting scheme if you want to use the motor you've already got.

For a bit more you could step up to a 7x14 or 7x16, but would likely need to come up with your own motor mounting scheme if you want to use the motor you've already got.