- Joined

- Jan 20, 2015

- Messages

- 93

Thank you - that makes sense.

My spindle is 2mt. While digging through the tools left to me I found two Bridgeport (so labeled) 2mt collets. They seem to fit the machine and draw bar, but they won't bite down and hold the tool. Any thoughts?

My spindle is 2mt. While digging through the tools left to me I found two Bridgeport (so labeled) 2mt collets. They seem to fit the machine and draw bar, but they won't bite down and hold the tool. Any thoughts?

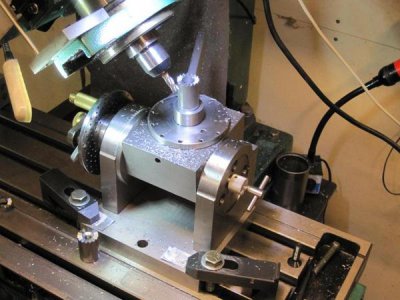

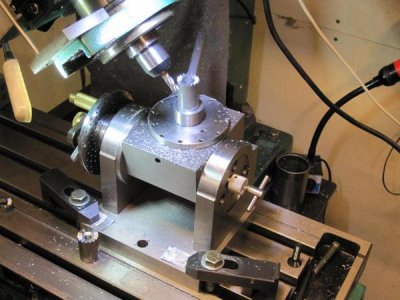

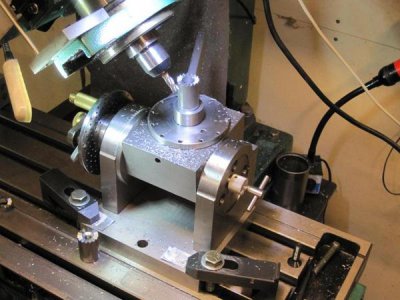

There is a lot of tool/holder sticking out from the spindle, if you have a collet that will hold the endmill in the spindle then that would help the setup. It's OK to use it that way, but it is less ridged than having a shorter setup. You just have to compensate by taking lighter cuts.

It looks like the width of the cut is greater than 1/2 the diameter of the end mill, that can tend to pull the tool into the work. This may be why the endmill is chipping. I would make that cut in 2 passes on the width with a springy setup, maybe 1/4 the diameter of the endmill.