- Joined

- Jan 20, 2015

- Messages

- 93

Hello everyone,

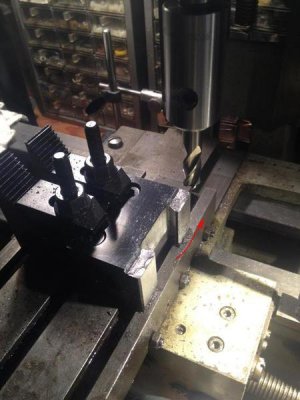

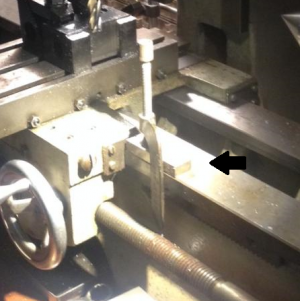

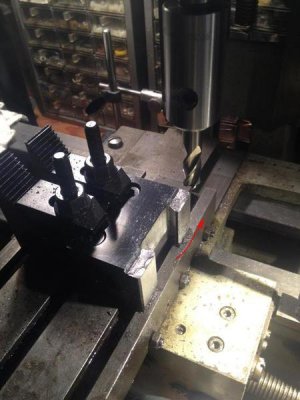

I'm new to milling and I'm trying to learn on my Maximat Compact lathe with vertical mill. One of my early projects is to remove .150 off of some Chinese made quick change tool holders for the lathe. I'm using a 1/2" four fluke endmill and I'm removing .050 in each pass. My problem is that I keep chipping of the cutting tips of the endmill. The first dovetail pass goes pretty well (see Fig. 1 and note the arrow indicated the bed travel direction) the second dovetail pass is a little more choppy and by the time I've finished removing the whole .150 my tool is pretty chipped up.

I'm feeding ad a very slow rate (because I'm scared) and I'm using oil.

Any advice would be greatly appreciated.

~ Carl

Fig. 1

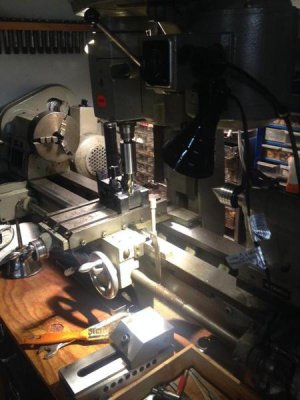

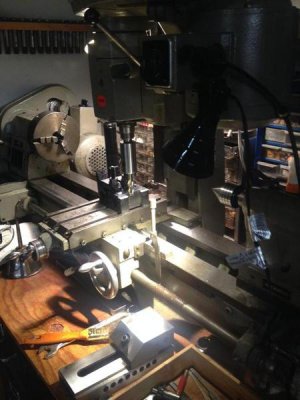

Fig. 2

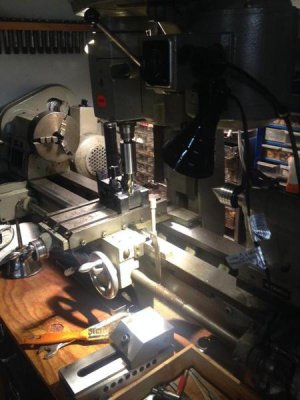

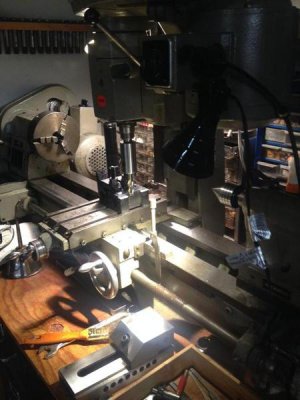

My machine

I'm new to milling and I'm trying to learn on my Maximat Compact lathe with vertical mill. One of my early projects is to remove .150 off of some Chinese made quick change tool holders for the lathe. I'm using a 1/2" four fluke endmill and I'm removing .050 in each pass. My problem is that I keep chipping of the cutting tips of the endmill. The first dovetail pass goes pretty well (see Fig. 1 and note the arrow indicated the bed travel direction) the second dovetail pass is a little more choppy and by the time I've finished removing the whole .150 my tool is pretty chipped up.

I'm feeding ad a very slow rate (because I'm scared) and I'm using oil.

Any advice would be greatly appreciated.

~ Carl

Fig. 1

Fig. 2

My machine