-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling A Gib Strip

- Thread starter savarin

- Start date

- Joined

- Nov 21, 2015

- Messages

- 56

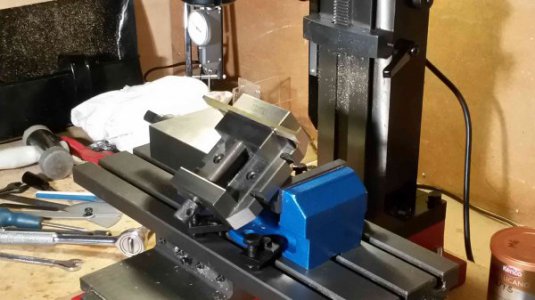

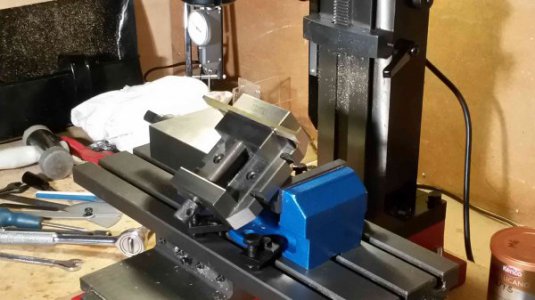

I made one for the x axis on my sx2 mill soon after I got it as the factory supplied one didn't fit in the dovetails very well and was shaped like a banana. As there was enough overlap on the long parallel sides I held it like this:

The little vice is bolted to a length of 1-1/2" rod with a flat milled on it. I took light cuts to avoid distorting the unsupported ends. The end result adjusted up much better than the original and has been working ever since.

Rob

The little vice is bolted to a length of 1-1/2" rod with a flat milled on it. I took light cuts to avoid distorting the unsupported ends. The end result adjusted up much better than the original and has been working ever since.

Rob

4

4GSR

Forum Guest

Register Today

You essentially have to make a fixture that has a 30 deg or 60 deg edge milled on it hold the piece in place. And make a full length hold down strap to hold the brass piece while milling the angle needed.

A

Andre

Forum Guest

Register Today

Bench vise and a file

4

4GSR

Forum Guest

Register Today