My new mill is down. So while I'm waiting for Mr. Technician to arrive, I figured I'd post & solicit some advice. It was running fine & then it seemed to me the motor started making a noise that didn't sound right. Then it tripped the breaker. The motor noise didn't really sound 'mechanical' like grinding or friction, but I'm no expert & maybe this was wishful thinking. Anyway, no heavy load or anything like that. Maybe a couple hours of cumulative running time. A few repeat tries of this startup with & no progress. If I start it in neutral it ran a tad longer (but always rough sounding) then trips breaker. If I put it into gear it trips breaker almost immediately. The motor is a 240V single phase 3 hp.

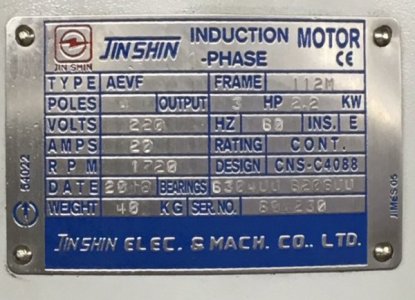

Tech visit number #1. <insert self ass-kick here> The first thing he notices is my panel breaker is 15A & the motor is 20A. DOH! Nowhere in my purchasing discussions did the topic of available amp duty come up. Its not even specified in the brochure or Taiwan manual. Now I am smarter about such worldly matters & will never make this error again. I will ask for motor plate specs up front. Anyway, I'm told start-up current can be higher than running current, so this needed to be dealt with first.

So I just finished installation of new 40A breaker on my panel, ran a dedicated AC 8/3 ( 8 gauge 40A) armored cable direct line & 240V 40A outlet to my mill area & new range style plug on the mill. Now I can use this outlet or at least this upgraded line for a TIG welder one day. Measure 240V at the panel, 240V at the plug, so far so good. I plugged the mill in, flicked the switch on for 2 seconds, it started immediately. But to my ear the exact same kind of ratchety sound. I started again, ran it for about maybe 5 seconds and then BANG. Pretty sure the capacitor blew because I think that's what lives in the little cover pod on the motor side & where lots of magic smoke came from. Well, crap!

This got me Googling motor capacitors & related problems. I found this article & similar ones that suggest if the centrifugal switch is faulty, then it can overload the capacitors. https://cdn0.grizzly.com/manuals/g2529_m.pdf

Maybe the capacitor was bad or incorrect spec. We will never know because it surely must be shrapnel. Do you think its possible that the centrifugal switch migrated or slipped out of position & was the main culprit all along? Do you think my low 15A breaker configuration was tripping early & prolonging the inevitable when it finally had full 40A & went pop?

I cant see any detail in my 'abbreviated' user manual for the motor itself. Do you think my centrifugal switch / related hardware might be on top of the motor can where it could be readily examined & replaced without hauling that big muther motor off? Anything else you can think of that could explain this situation? Can windings & such be diagnosed on the machine?

Tech visit number #1. <insert self ass-kick here> The first thing he notices is my panel breaker is 15A & the motor is 20A. DOH! Nowhere in my purchasing discussions did the topic of available amp duty come up. Its not even specified in the brochure or Taiwan manual. Now I am smarter about such worldly matters & will never make this error again. I will ask for motor plate specs up front. Anyway, I'm told start-up current can be higher than running current, so this needed to be dealt with first.

So I just finished installation of new 40A breaker on my panel, ran a dedicated AC 8/3 ( 8 gauge 40A) armored cable direct line & 240V 40A outlet to my mill area & new range style plug on the mill. Now I can use this outlet or at least this upgraded line for a TIG welder one day. Measure 240V at the panel, 240V at the plug, so far so good. I plugged the mill in, flicked the switch on for 2 seconds, it started immediately. But to my ear the exact same kind of ratchety sound. I started again, ran it for about maybe 5 seconds and then BANG. Pretty sure the capacitor blew because I think that's what lives in the little cover pod on the motor side & where lots of magic smoke came from. Well, crap!

This got me Googling motor capacitors & related problems. I found this article & similar ones that suggest if the centrifugal switch is faulty, then it can overload the capacitors. https://cdn0.grizzly.com/manuals/g2529_m.pdf

Maybe the capacitor was bad or incorrect spec. We will never know because it surely must be shrapnel. Do you think its possible that the centrifugal switch migrated or slipped out of position & was the main culprit all along? Do you think my low 15A breaker configuration was tripping early & prolonging the inevitable when it finally had full 40A & went pop?

I cant see any detail in my 'abbreviated' user manual for the motor itself. Do you think my centrifugal switch / related hardware might be on top of the motor can where it could be readily examined & replaced without hauling that big muther motor off? Anything else you can think of that could explain this situation? Can windings & such be diagnosed on the machine?

Last edited: