- Joined

- Dec 9, 2016

- Messages

- 1,133

I agree very nice.

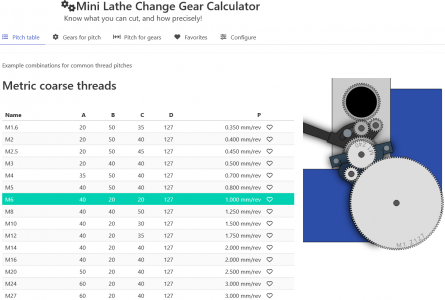

Here is the thread chart, picture and a pdf

Bob are you sure about the 127/120 combination? I was under the impression it was 127/100. I have a 127 tooth to fit my lathe and am looking around for a 100 tooth gear, but they are spendy. 127/100 combo is a close enough approximation to work on any imperial lead screw but the lesser tooth combinations seem to work out only for certain imperial leadscrew TPIs and are limited to the number of metric pitches they can cut. My Lathe does not have a QC gearbox, only change gears. A QC gearbox may open up more possibilities than I'm aware of.Hi, The Most accurate way to cut metric threads on an imperial lathe is to use the 127 x 120 tooth gear set. This works very well as 127 is half of 254, so 25.4 mm to the inch exactly, and you can get pretty much all the common metric threads from your norton thread box.

The 127 x 120 tooth gears will fit moist medium and larger lathes, but many smaller lathes have to use an approximation set of gears commonly 63 x 60, and there are others. While the threads produced by these approximation methods are accurate enough for short bolts and nuts, they will produce small errors that add up in longer threads. They are not suitable for making a lead screw for instance.

There are a number of charts available on the web and some here on HM that will help you. Good luck.

Bob are you sure about the 127/120 combination? I was under the impression it was 127/100. I have a 127 tooth to fit my lathe and am looking around for a 100 tooth gear, but they are spendy. 127/100 combo is a close enough approximation to work on any imperial lead screw but the lesser tooth combinations seem to work out only for certain imperial leadscrew TPIs and are limited to the number of metric pitches they can cut. My Lathe does not have a QC gearbox, only change gears. A QC gearbox may open up more possibilities than I'm aware of.