First post! Desperate!

I have at 1334 MIL lathe that I use for my side machining business. I have single-tooled many a inch threads no problem. Now I have a job calling for metric threads, M65x2 and I'm stumped. See from attached pictures from my machine that I have the metric capability. I can select the correct feed from the quick change gear box to get 2mm pitch no problem.

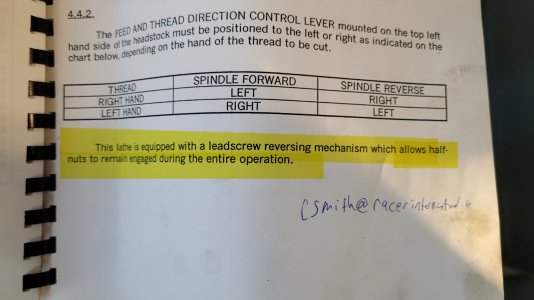

However, as has been well documented that since I have an inch leadscrew and inch travel dial, I must leave the half nut engaged throughout the threads. That's where my problem comes in.

1) My first inclination was to engage half-nut, make my first cut, and switch the direction of the leadscrew using upper left lever on the head stock while it's running. During the reversal process, there is a brief pause of the leadscrew while the reversal happens, all the while the spindle is turning. Thus I lose my timing. I've verified this by attaching a pen to my tool holder, and the pen lines DO NOT match up.

2) After scouring the internet, I found this method (

) and gave it a shot. Same issue happens, when I reverse the spindle, the lead screw noticeably pauses when switching directions. In this video, the lead screw speed is 100% synced to the spindle, mine is not. Using the pen check, again I lose the sync using this method.

3) Lastly, I found this video of a standard modern lathe that goes into detail about the "Lead Screw Reversing Mechanism."

. Im 99.99% sure I don't have this "Lead Screw Reversing mechanism mentioned in this video.

4) What really bothers me is that my manual says I have a lead screw reversing mechanism which allows the half nut to stay engaged. So, I called up Racer International (aka Standard Modern) and they were not helpful. They pointed out that the lead screw reversing mechanism is the lever on the head stock. Well, it definitely reverses the lead screw direction, but as I noted previously, the lead screw will pause briefly while spindle is still turning which to me is absolutely useless when making threads.

I'm somewhere between a newbie and a wannabe machinist, so I assuming I'm missing something. But it seems to me that the lead screw reversal on this particular lathe is non-typical. I really need to get this figured out for this customer. Does anyone have experience machining metric threads on a 1334-MIL? Many thanks.

I have at 1334 MIL lathe that I use for my side machining business. I have single-tooled many a inch threads no problem. Now I have a job calling for metric threads, M65x2 and I'm stumped. See from attached pictures from my machine that I have the metric capability. I can select the correct feed from the quick change gear box to get 2mm pitch no problem.

However, as has been well documented that since I have an inch leadscrew and inch travel dial, I must leave the half nut engaged throughout the threads. That's where my problem comes in.

1) My first inclination was to engage half-nut, make my first cut, and switch the direction of the leadscrew using upper left lever on the head stock while it's running. During the reversal process, there is a brief pause of the leadscrew while the reversal happens, all the while the spindle is turning. Thus I lose my timing. I've verified this by attaching a pen to my tool holder, and the pen lines DO NOT match up.

2) After scouring the internet, I found this method (

3) Lastly, I found this video of a standard modern lathe that goes into detail about the "Lead Screw Reversing Mechanism."

4) What really bothers me is that my manual says I have a lead screw reversing mechanism which allows the half nut to stay engaged. So, I called up Racer International (aka Standard Modern) and they were not helpful. They pointed out that the lead screw reversing mechanism is the lever on the head stock. Well, it definitely reverses the lead screw direction, but as I noted previously, the lead screw will pause briefly while spindle is still turning which to me is absolutely useless when making threads.

I'm somewhere between a newbie and a wannabe machinist, so I assuming I'm missing something. But it seems to me that the lead screw reversal on this particular lathe is non-typical. I really need to get this figured out for this customer. Does anyone have experience machining metric threads on a 1334-MIL? Many thanks.