I would think that setting the tube upright on a surface plate and using a precision machinist's square at four points around the circumference to check for square should be adequate. This would need to be done for both ends.

As an alternative, a person could use a height gauge and a surface plate to give you an indication of square with high probability. I know, some of you are going to want to argue this one, but

please read the rest of what I have to say before you start typing a response.

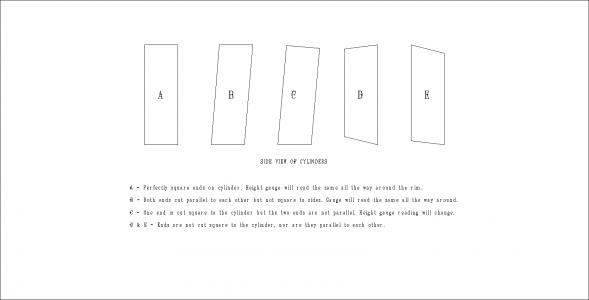

When a cylinder is cut to length, the two ends will usually not be perfectly parallel to each other, nor will they be perfectly square to the sides. Cutting with a saw or similar device is just simply not a high precision process in most cases. Bob Korves is correct that it is

possible for the same height gauge reading to be had all around the rim of the cylinder but it will not be square. However it is

highly improbable that this would occur. For that to happen, the two ends would need to be cut perfectly parallel with one another, in other words they would both need to be cut crooked by exactly the same amount and in the same orientation to the cylinder. I am not saying that it cannot happen, but I am saying that it is

highly unlikely.

So, for that reason, one could quickly check for square of a cylinder by standing it on a surface plate and checking the height all around the rim. If the same reading is obtained all the way around, there is a high likelihood that the cylinder is square on both ends. A quick check with a precision machinist's square would back up that conclusion. The attached illustration should help to demonstrate what I am getting at. Keep in mind that the out of square errors are greatly exaggerated in the drawing.

View attachment 118769