I'd really love to do a line drive from the ceiling along with a few other vintage machines, drill press, shaper, trip hammer, but that's gonna have to wait. I have another cone machined out of aluminum with a bracket that mounts on top with a short belt I'll post a photo once I get it set up. I'm waiting to find a suitable motor. He told me 3 to 5 horse?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- GENERAL TYPES OF METALWORKING MACHINES

- ANTIQUE & VINTAGE MACHINERY

- MISC ANTIQUE & VINTAGE MACHINERY

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

McKenzie Lathe

- Thread starter Mike Hage

- Start date

- Joined

- Oct 18, 2016

- Messages

- 2,872

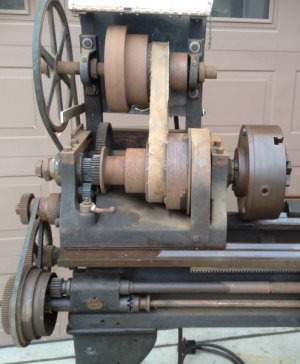

Mike, looks great. Can you post some more photos around the head stick? I'm interested in the countershaft setup and what looks to be some oilers on the spindle

Sent from my iPhone using Tapatalk

That shaft doesn't look like a counter shaft: it looks like it's set up for back gear. You can see the pin on the bull gear,

and it looks as though the shaft is mounted on an eccentric.

- Joined

- Feb 2, 2013

- Messages

- 3,973

the lathe is awesome!

i love the old iron!!

are you gonna use a cantilevered drive or an overhead arrangement for the drive motor ?

i have an antique Flather lathe that was modified long ago with an overhead arrangement.

i love the old iron!!

are you gonna use a cantilevered drive or an overhead arrangement for the drive motor ?

i have an antique Flather lathe that was modified long ago with an overhead arrangement.

the lathe is awesome!

i love the old iron!!

are you gonna use a cantilevered drive or an overhead arrangement for the drive motor ?

i have an antique Flather lathe that was modified long ago with an overhead arrangement.

Bear with me I'm very new to this. What is a counter shaft? There is kind of a transmission on the front?View attachment 279969

That shaft doesn't look like a counter shaft: it looks like it's set up for back gear. You can see the pin on the bull gear,

and it looks as though the shaft is mounted on an eccentric.

Not sure what a cantilevered drive is. I have a bracket with a stepped pulley and a short belt. I will post pics once I get it mounted. It's kinda ugly I'd really like to do a line drive from the ceiling. All my old men that I could ask about these things are dying or gone already. What does your drive look like?the lathe is awesome!

i love the old iron!!

are you gonna use a cantilevered drive or an overhead arrangement for the drive motor ?

i have an antique Flather lathe that was modified long ago with an overhead arrangement.

- Joined

- Feb 2, 2013

- Messages

- 3,973

Not sure what a cantilevered drive is. I have a bracket with a stepped pulley and a short belt. I will post pics once I get it mounted. It's kinda ugly I'd really like to do a line drive from the ceiling. All my old men that I could ask about these things are dying or gone already. What does your drive look like?

this overhead arrangement was done in the late 40's or early 50's, if i had to guess.

here is a picture of the drive on the ol' Flather

- Joined

- Oct 18, 2016

- Messages

- 2,872

Bear with me I'm very new to this. What is a counter shaft? There is kind of a transmission on the front?View attachment 280131

Lathes with back gear capability basically give you a kind of high and low range for spindle speed. Have a look at the secondary

shaft. On the end is a lever, which should allow you to engage and disengage the gears on that shaft with the gears on the

spindle. Now look at the bull gear (larger gear on the tailstock end of the spindle). On the side is a flat headed pin. By pulling

that pin out or pushing it in, you should be able to disengage or engage the bull gear from the pulleys for the flat belt. In back gear (low range),

the shafts are in mesh and the pin on the bull gear should be out. Power passes through the secondary shaft and back to the

bull gear. With the pin in and the shafts not meshed together, the spindle

should turn faster for a given motor speed since it is in "direct drive".

The gearbox on the front is engaged to turn the shaft that passes through it and runs bellow the edge of the bed. Notice it

passes behind the apron on the carriage. When that shaft is turning, it should be possible to power feed the carriage

towards the headstock. Some lathes also can cross feed under power as well. It looks as though your lathe is missing

some parts, since there should be a gear train that connects the shaft on the gear box with the gears at the outboard

end of the spindle. Without those parts, you won't be able to power feed, but you still can turn parts manually.

Does anyone know what type of oil I should use for those big bushings on the headstock?