- Joined

- Dec 15, 2021

- Messages

- 3

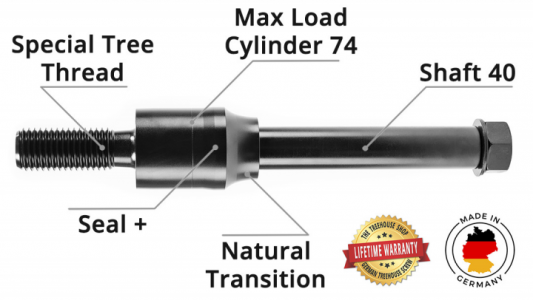

Hi guys, I am wanting to make some treehouse attachment bolts but I am unsure on the best way to tackle this thread.

I am using a manual lathe, the bolt will be 40mm diameter and be made from 4140 steel with a 5mm pitch thread.

1.how would you achieve the below thread style with the wider root?

I was thinking I could grind a hss steel to match, like in the photo, but not sure if this should be the exact width of the root, so come in like a plunge cut, or have it narrower, so come in to depth and then move the cross slide across to widen it up. Will HSS leave a good finish with 4140? Happy to answer any other questions. thank you!

I am using a manual lathe, the bolt will be 40mm diameter and be made from 4140 steel with a 5mm pitch thread.

1.how would you achieve the below thread style with the wider root?

I was thinking I could grind a hss steel to match, like in the photo, but not sure if this should be the exact width of the root, so come in like a plunge cut, or have it narrower, so come in to depth and then move the cross slide across to widen it up. Will HSS leave a good finish with 4140? Happy to answer any other questions. thank you!