Well, it’s been a hectic couple weeks for me, but I finally got some shop time to work on the gib. This was my setup on the mill. I made two stops from some drill rod and indicated them to be in line with the long axis of the table. Then clamped the finished edge of my stick to them with a stack of feeler gauges in one end to produce the correct angle (kinda like a sine bar).

View attachment 386140

After clamping it down to the table, I removed the Kant twist clamps and milled a groove to an adequate depth.

View attachment 386141View attachment 386142

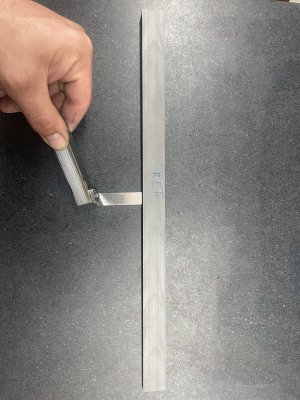

I then brought the gib to final thickness by side milling and freed it with a slitting saw.

View attachment 386143

I’m pretty happy with it so far. It did acquire a slight bow (0.003”) as measured with feeler gauges on the surface plate.

View attachment 386144View attachment 386145

I won’t be surprised if I get some more warpage when I mill the 60 degree edges. My plan is to use a dovetail cutter like Kieth Rucker did in one of his recent videos on his Monarch restoration. I’m waiting on some tooling to arrive, so no more progress for now.