- Joined

- Nov 23, 2020

- Messages

- 820

Hi all,

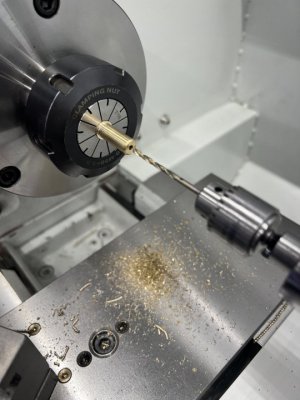

So after numerous broken drills, I have decided to make a Joe P style sensitive drill for my lathe. The chuck I am using is a tiny 0 to .25 Llambrich , and I ordered a 0JT to 1/2” straight shank arbor. My thinking was to machine a 3MT adaptor to insert directly into my tail stock, and ream to .501 for a no slop slip fit. Alternatively, I could fit 5/8” into my keyless chuck, and ream that to .501.

First, what do you suggest here?

Second - If I were to machine the 3MT insert, would you recommend:

Drill to pre ream size, ream. Then machine the MT in same set up with fat side towards tail stock,, test fit on my pass through headstock dead center adaptor, and part off? This would include machining a “tang” on one side just smaller than the small diameter of a 3MT, and then flip it and put in an ER40 collet for drilling, reaming, and machining the taper. Once the hole is reamed I could chamfer and use a live center for support while machining the taper for the tail stock, but would need to remove it to test fit.

Or

Machine the 3MT first, and then flip the part and mount it in my head stock 3MT adaptor after fitting, seat with brass mallet, and then drill, and ream from tail stock? This could risk breaking the taper and galling, but I doubt forces would be that high.

Or

Something completely different.

Thoughts?

So after numerous broken drills, I have decided to make a Joe P style sensitive drill for my lathe. The chuck I am using is a tiny 0 to .25 Llambrich , and I ordered a 0JT to 1/2” straight shank arbor. My thinking was to machine a 3MT adaptor to insert directly into my tail stock, and ream to .501 for a no slop slip fit. Alternatively, I could fit 5/8” into my keyless chuck, and ream that to .501.

First, what do you suggest here?

Second - If I were to machine the 3MT insert, would you recommend:

Drill to pre ream size, ream. Then machine the MT in same set up with fat side towards tail stock,, test fit on my pass through headstock dead center adaptor, and part off? This would include machining a “tang” on one side just smaller than the small diameter of a 3MT, and then flip it and put in an ER40 collet for drilling, reaming, and machining the taper. Once the hole is reamed I could chamfer and use a live center for support while machining the taper for the tail stock, but would need to remove it to test fit.

Or

Machine the 3MT first, and then flip the part and mount it in my head stock 3MT adaptor after fitting, seat with brass mallet, and then drill, and ream from tail stock? This could risk breaking the taper and galling, but I doubt forces would be that high.

Or

Something completely different.

Thoughts?