Don't know what happened, but somehow I stopped getting messages for posts to this thread, maybe somewhere around post #30. Still shows that I am following the thread. I missed a lot of good stuff, guys!

As I understand things, many pro grinder hands like electromagnetic chucks over permanent magnet chucks specifically because they can control the power of the the magnetic flux to get only what they need. Thin work wants to warp on the chuck if clamped too hard. Any parts are more likely to be pulled down to positions that are not parallel with the machine axes when clamped too hard. Experienced grinder hands know how much magnetic force is needed to hold down the work, and do not use more than enough to just hold parts down when chasing tenths -- as I understand things. I am certainly not experienced enough to be able to even know what is necessary to hold any particular part on a given chuck against a given cut, and at this point just want a good, safe hold on the part. If I cannot move the part by hand, I am happy. But that might change. I also plan to use my chuck for scraping in parts, bench work, and perhaps on the milling machine, which can both involve thin parts as well.

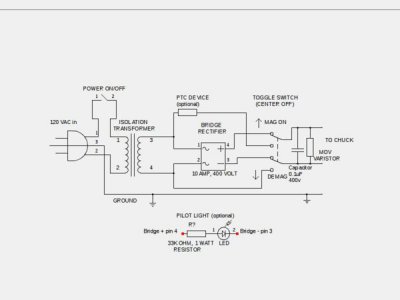

I must confess to not knowing what a PTC device is, or a MOV varistor, and what they do for us. Also note that my old school mag chuck has a two prong 115V wall plug on the petrified two wire cable that I have not changed out yet. It plugged into an old selenium rectifier with a two wire receptacle, this is a commercial rig. Were they tempting fire, or being smart? I definitely do not show continuity between the mag chuck exterior and the two power wires. My current plan definitely is to use a variac for the input AC and a 450V 470 mf cap to smooth the current between rectifier and chuck, at least until I learn otherwise. I am trainable, however.

I am concerned that a GFI might make it more likely to lose mag power to the chuck, which can be a really bad thing, throwing parts off a grinder is a bad idea to be carefully avoided. Beyond that, the part moving may result in a major crash, exploding the wheel and damaging the grinder, not to mention the health of the operator. This is pretty serious business, not to be taken lightly.

Educate me, please...