- Joined

- Sep 22, 2019

- Messages

- 1,049

Tapping some 1/2" 13TPI holes in 3/8" stock for Cub Cadet lift arm parts when I noticed the threads didn't look quite right, peaks were kind of flat and the bolt felt loose when turned in. This on the 3rd part out of the 6 I planned to make.

Brand new spirol tap, first use with plenty of oil, noticed it turned in easily too! Wow! these new fangled spirol 3 flute taps are really the cat's Meow!!

The tap looked good when compared with my old Craftsman tap, although both felt loose in the bore as well.

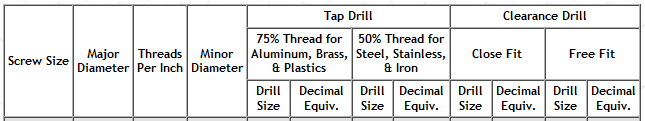

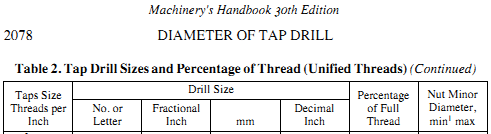

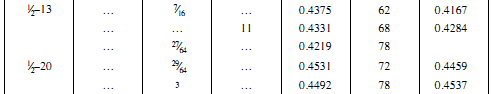

LMS chart spec's 29/64" drill bit.

Craftsman chart that I checked after noticing this says 27/64"

Tried that bit and tapped some test holes and they turned out perfect and it turned a bit harder as well.

Glad I caught it when I did!

I think I will call them tomorrow and inform them they have a typo on that chart.

GRRRRR!!

Makes me kinda wonder if there are more than that one typo on that chart!

Brand new spirol tap, first use with plenty of oil, noticed it turned in easily too! Wow! these new fangled spirol 3 flute taps are really the cat's Meow!!

The tap looked good when compared with my old Craftsman tap, although both felt loose in the bore as well.

LMS chart spec's 29/64" drill bit.

Craftsman chart that I checked after noticing this says 27/64"

Tried that bit and tapped some test holes and they turned out perfect and it turned a bit harder as well.

Glad I caught it when I did!

I think I will call them tomorrow and inform them they have a typo on that chart.

GRRRRR!!

Makes me kinda wonder if there are more than that one typo on that chart!

Last edited: