- Joined

- Mar 13, 2017

- Messages

- 36

I'd like to start off with a big hello, I am totally new to this forum and this is my first post.

I own a Ruger american in .223 and the stock is pretty lacking. The plastic stock flexes so much while shooting at a bench that stock really is no longer free floating. When I stumbled upon these so called "chassis" system's I kind of fell in love with the idea. They are super ridged, dissipate heat from the action, and in my opinion kind of look cool even though I'm sure most traditional guys clench a fist at the idea of one.

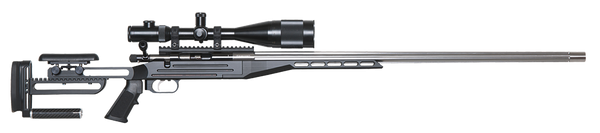

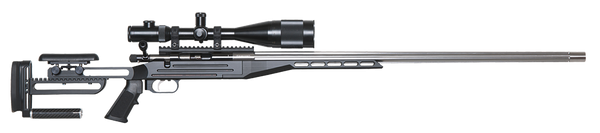

Being a self-supporting college student there was not way I could afford to spend 500 bucks on one. I have a pretty extensive machining background, so I figured I could make one . I have access to several university shops so lack of tooling is no concern. I have a pretty good idea on my different set-ups and operations, my questions lie mostly in the design. I have a lot of machining experience but have never really bridged the gap between machining and gunsmithing, if you could even call this project gunsmithing. Therefor I don't really know the functionality of some of the stock inletting on the molded stock. I plan on using the internals of the original stock as a reference and the exterior will just be machined to my cosmetic liking. I think I'll copy a lot of the exterior of the first image which doesn't look too complicated considering all be doing all the milling manually without the use of a CNC. I will definitely be using a thread on AR style stock as well just out of simplicity. I have the Ruger American Ranch, which only has a 16.2 inch barrel so my overall piece of 6061 will end up being roughy 1.5x3x 12-16" depending on what I can get for cheap on ebay.

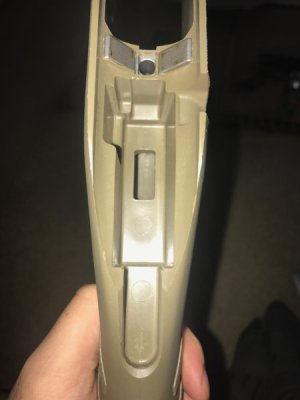

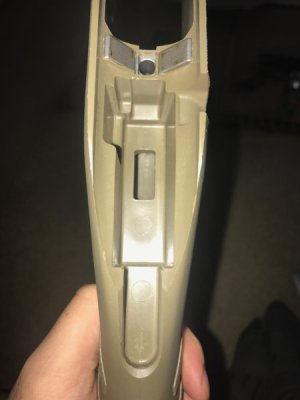

The Ruger American uses what Ruger calls, "power-bedding" to bed the action (I HAVE INCLUDED PHOTOS OF THE STOCK IN THE LINKS). Its the two steel v-shapes that the stock is molded around. The action contacts the stock on the flats of those v's and only those 4 points. There is not recoil lug or anything like that , just those v-blocks. I would imagine that any other cutaway in the stock is just clearance for other parts of the action. So one of my main questions is, if I were to mill the pocket for the trigger assembly as a flat bottom pocket roughly matching the shape in the photo, as long there is clearance for everything, it shouldn't really matter right?

My second major question being, "As long as I mill the magazine well to about the right size, and included the notches at the front and back for the magazine to catch on, that should work fine enough to avoid feeding problems. This one might seem to answer itself I just figured as long as I'm writing this memoir of a post I might as well be doubly sure.

Final question, the shops have horizontal mills, but being on spring break I am not sure if they have a 1 3/8 convexed radius cutter that would be needed to do the main inletting of the barrel, if they don't any ideas on cutting that radius cove without either a horizontal milling cutter or a large ball nosed end mill.

Any help would be greatly appreciated, sorry for the super long post.

I own a Ruger american in .223 and the stock is pretty lacking. The plastic stock flexes so much while shooting at a bench that stock really is no longer free floating. When I stumbled upon these so called "chassis" system's I kind of fell in love with the idea. They are super ridged, dissipate heat from the action, and in my opinion kind of look cool even though I'm sure most traditional guys clench a fist at the idea of one.

Being a self-supporting college student there was not way I could afford to spend 500 bucks on one. I have a pretty extensive machining background, so I figured I could make one . I have access to several university shops so lack of tooling is no concern. I have a pretty good idea on my different set-ups and operations, my questions lie mostly in the design. I have a lot of machining experience but have never really bridged the gap between machining and gunsmithing, if you could even call this project gunsmithing. Therefor I don't really know the functionality of some of the stock inletting on the molded stock. I plan on using the internals of the original stock as a reference and the exterior will just be machined to my cosmetic liking. I think I'll copy a lot of the exterior of the first image which doesn't look too complicated considering all be doing all the milling manually without the use of a CNC. I will definitely be using a thread on AR style stock as well just out of simplicity. I have the Ruger American Ranch, which only has a 16.2 inch barrel so my overall piece of 6061 will end up being roughy 1.5x3x 12-16" depending on what I can get for cheap on ebay.

The Ruger American uses what Ruger calls, "power-bedding" to bed the action (I HAVE INCLUDED PHOTOS OF THE STOCK IN THE LINKS). Its the two steel v-shapes that the stock is molded around. The action contacts the stock on the flats of those v's and only those 4 points. There is not recoil lug or anything like that , just those v-blocks. I would imagine that any other cutaway in the stock is just clearance for other parts of the action. So one of my main questions is, if I were to mill the pocket for the trigger assembly as a flat bottom pocket roughly matching the shape in the photo, as long there is clearance for everything, it shouldn't really matter right?

My second major question being, "As long as I mill the magazine well to about the right size, and included the notches at the front and back for the magazine to catch on, that should work fine enough to avoid feeding problems. This one might seem to answer itself I just figured as long as I'm writing this memoir of a post I might as well be doubly sure.

Final question, the shops have horizontal mills, but being on spring break I am not sure if they have a 1 3/8 convexed radius cutter that would be needed to do the main inletting of the barrel, if they don't any ideas on cutting that radius cove without either a horizontal milling cutter or a large ball nosed end mill.

Any help would be greatly appreciated, sorry for the super long post.

Last edited: