-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking at buying new Pm-949tv need help.

- Thread starter cv1911

- Start date

- Joined

- Oct 11, 2016

- Messages

- 4,008

The output of the VFD must to be hard-wired to the motor. No switch, nothing that can disrupt the circuit. The VFD relies on EMF feedback from the motor. All VFDs work this way. [ALL brands] Without a motor attached, the output IGBT or MOSFET stage will burn out in a less than a millisecond.Is there a reason why you can’t just have a VFD power the mills in put so you can use the original forward and reverse switch?Just use the VFD to convert 1phase to 3 phase and control rpm.

You can rewire the machine switch to do 'external control' on the VFD. This way you can keep the buttons that are handy and in a place you like...

- Joined

- Apr 30, 2015

- Messages

- 12,249

It seems this question never ceases to be asked- but the motor must be wired direct to the vfd, no switches.

If one wants to use the existing switches they need to be rewired to the low voltage control inputs of the vfd

and the vfd parameters set to use those inputs for things like stop/start and forward/reverse

If one wants to use the existing switches they need to be rewired to the low voltage control inputs of the vfd

and the vfd parameters set to use those inputs for things like stop/start and forward/reverse

- Joined

- Nov 19, 2018

- Messages

- 278

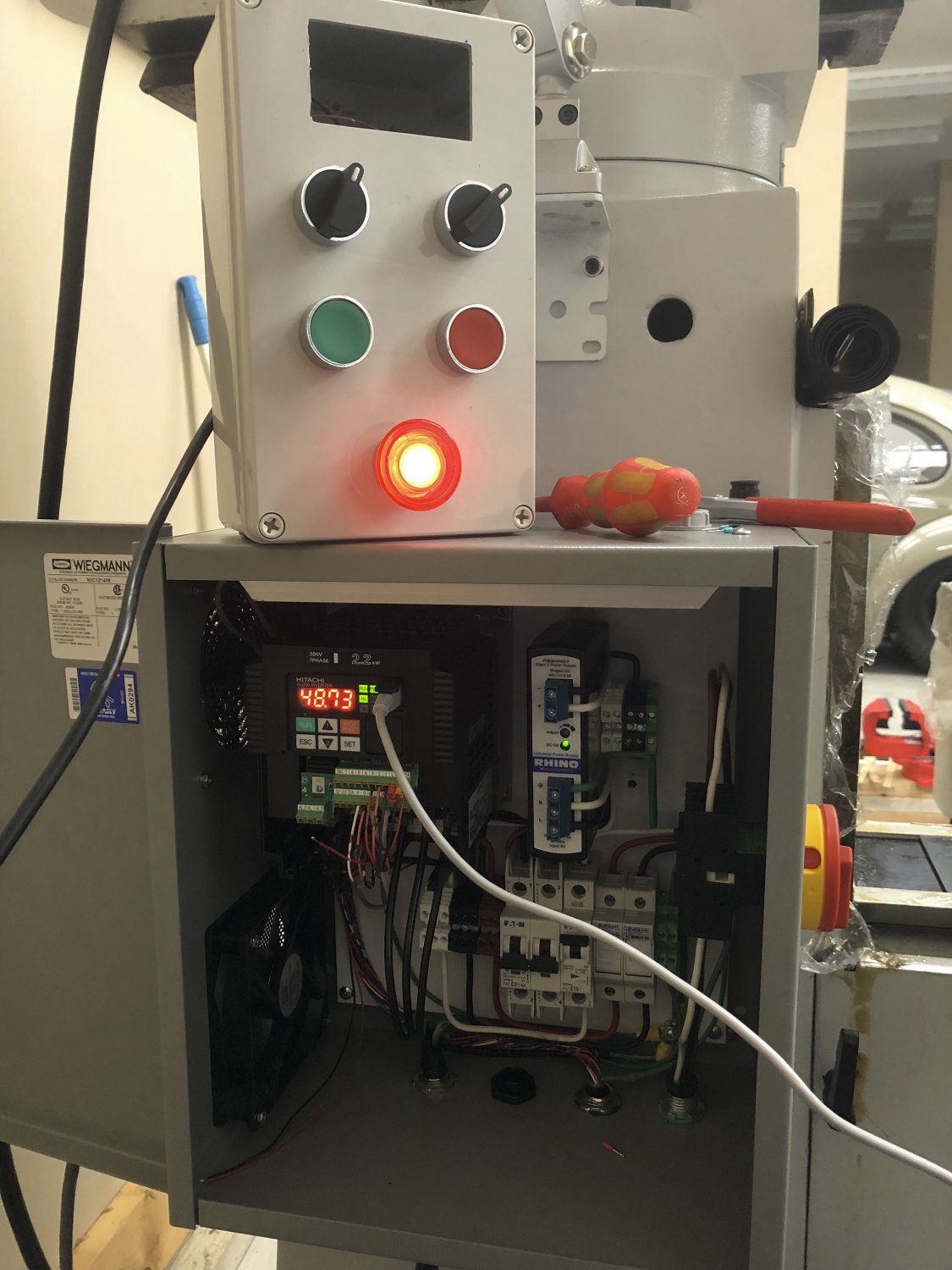

That whole "remote switches" and control where you'd like them is how you end up with that big box & all that stuff in the pic I posted. I have my control pod mounted conveniently for me at the front of the machine. That said - others do mount the VFD directly to the machine & control it via those buttons / switches etc., avoiding the need for the big ol' box.

Can you show me a pic of your control box with the switches? I was looking at that same Vfd. I would like a simple control box set up with forward/ reverse switch, speed control knob , E stop and maybe tachometer at some point. I would like to make it look professional. I was looking at some other posts on this and I like the box set up with the professional looking printed labels. I mean I could put switches in a box i just don’t want it to looked thrown together. I am sure this subject has be repeated a lot so I apologize. On some research I see a member designs, VFD set ups and is mentioned a lot. Does he sell his designs? I have an automotive background so I can follow some schematics but do not have any VFD experience. Did you design your set up? I am the type of guy that likes to do things myself and would like to try.That whole "remote switches" and control where you'd like them is how you end up with that big box & all that stuff in the pic I posted. I have my control pod mounted conveniently for me at the front of the machine. That said - others do mount the VFD directly to the machine & control it via those buttons / switches etc., avoiding the need for the big ol' box.

- Joined

- Dec 26, 2015

- Messages

- 2,148

You should start a conversation with Mark Jacobs (@mksj ) who builds VFD control systems for lots of people here on H-M. He has posted many times with detailed designs and schematics and is very helpful and a genuine nice guy. He built the control systems for my PM-935 and my PM-1340GT. If you want to make your own professional looking control panels, this is easily done through this company: https://www.frontpanelexpress.com/Can you show me a pic of your control box with the switches? I was looking at that same Vfd. I would like a simple control box set up with forward/ reverse switch, speed control knob , E stop and maybe tachometer at some point. I would like to make it look professional. I was looking at some other posts on this and I like the box set up with the professional looking printed labels. I mean I could put switches in a box i just don’t want it to looked thrown together. I am sure this subject has be repeated a lot so I apologize. On some research I see a member designs, VFD set ups and is mentioned a lot. Does he sell his designs? I have an automotive background so I can follow some schematics but do not have any VFD experience. Did you design your set up? I am the type of guy that likes to do things myself and would like to try.

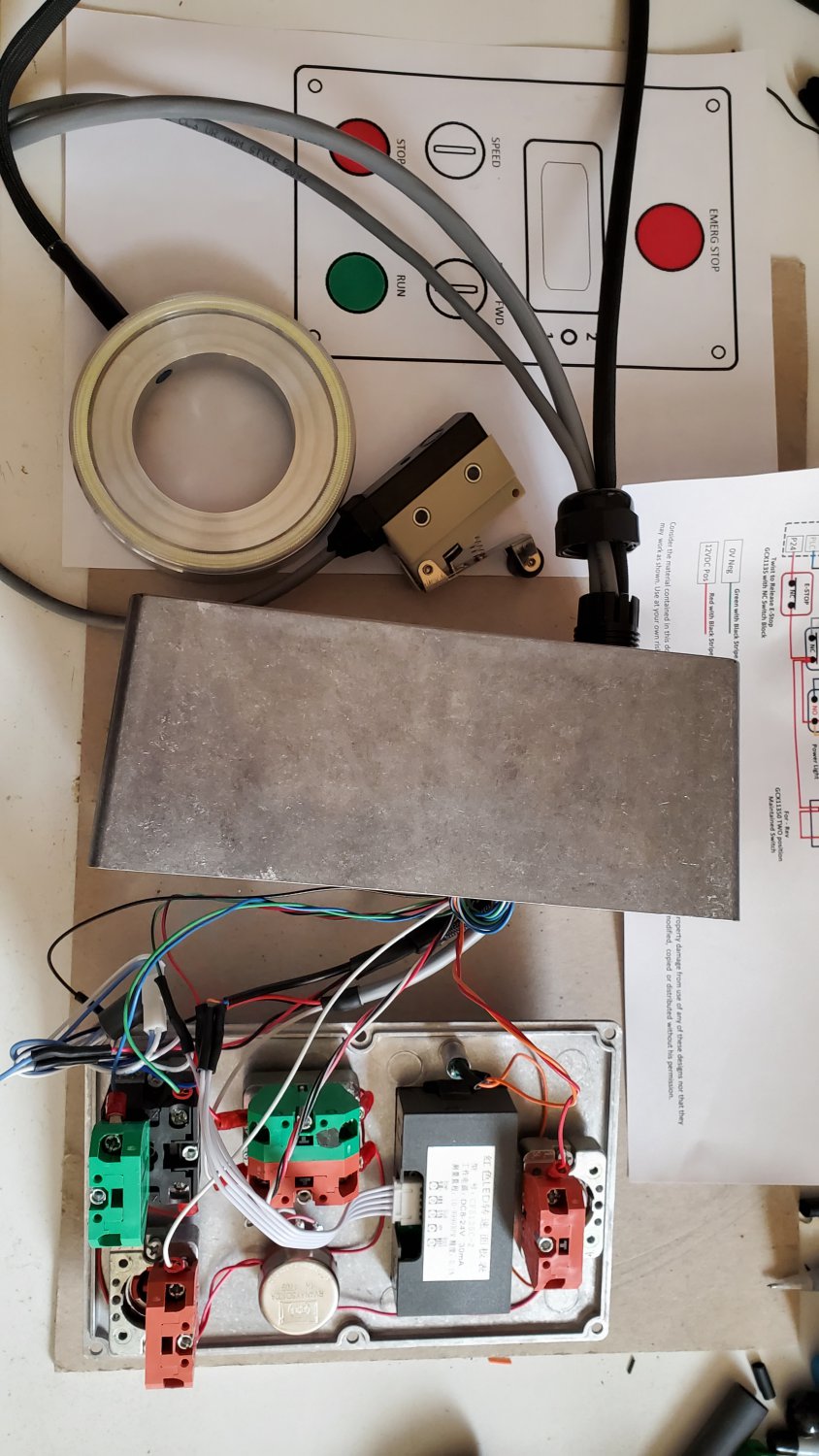

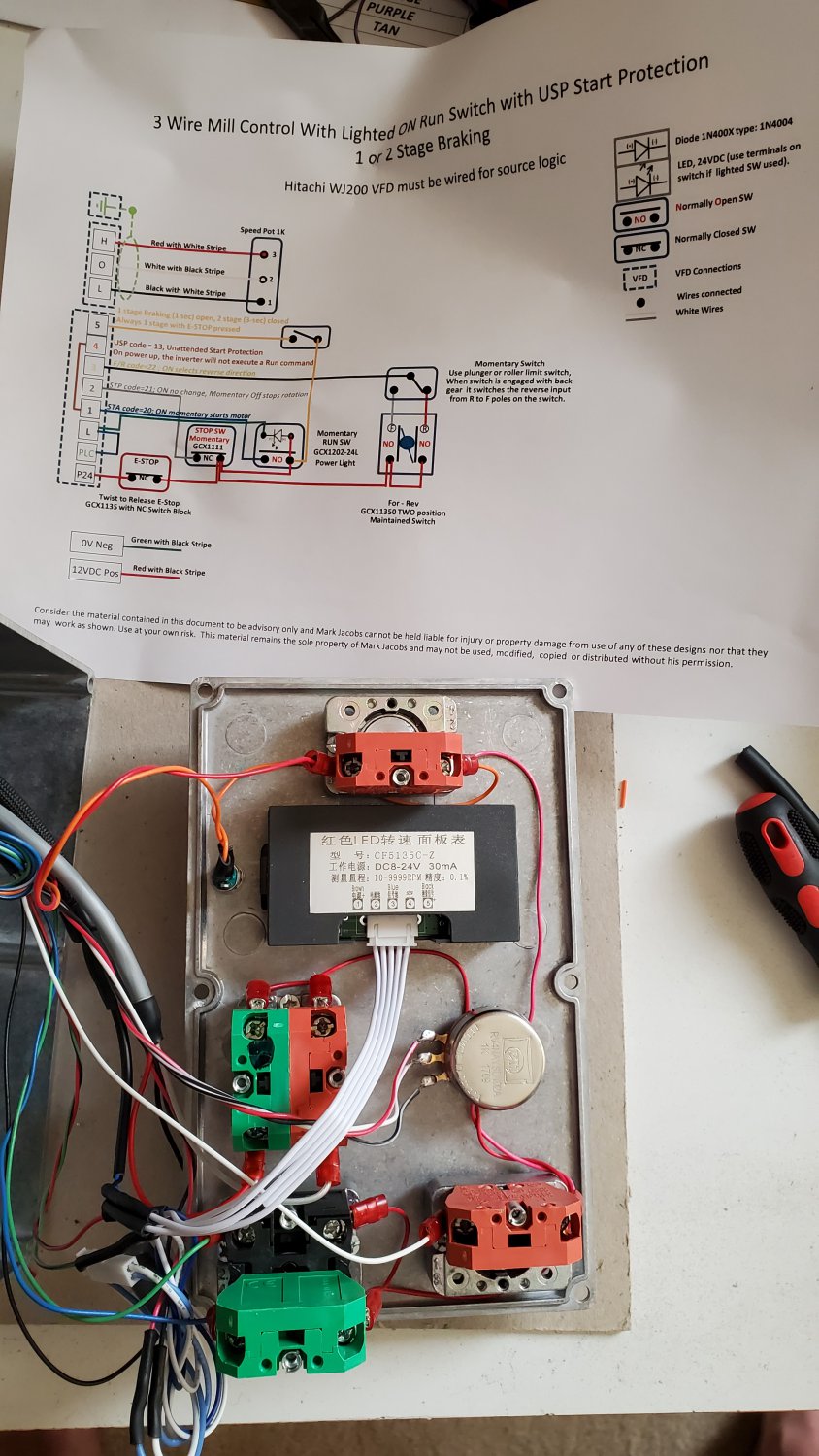

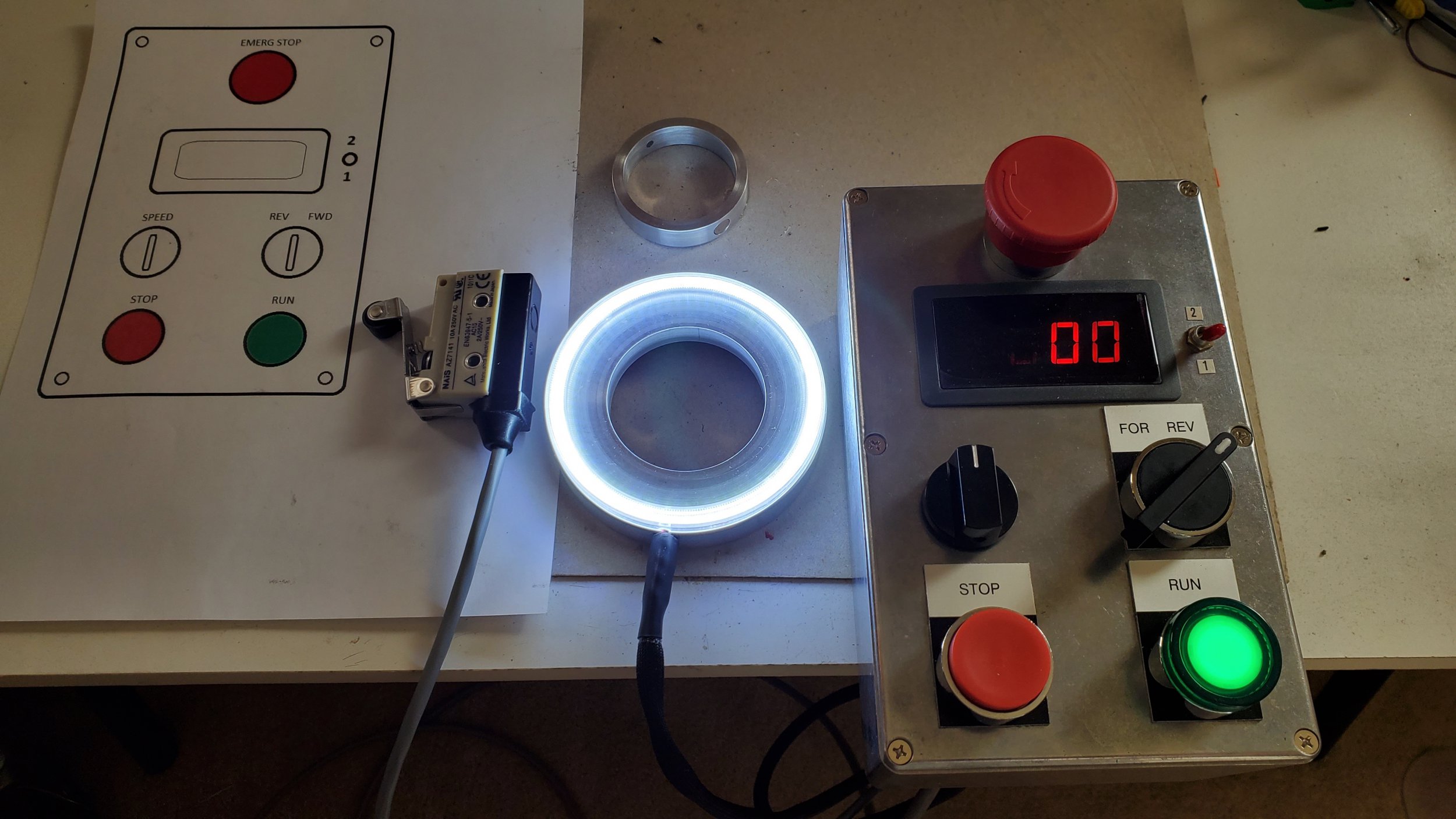

I designed and they fabricated the custom control panels for my machines as shown below:

I prefer some of the controls at waist height mounted to the knee and others mounted on the side of the J-head. The knee mounting is described here: https://flic.kr/s/aHBqjzyRHz

Thank you. Those are the control boxes I was referencing. I was thinking of just a simple setup mounted where the original power switch was. I just need to get a list of components together to start gathering parts. I want the control box small as possible. Its hard not having the switches in hand to see how big they actually are. Funny I was obsessing about a new milling machine now it has turned into obsessing about a VFD set up. Looking at everyone’s setup has got me overwhelmed. Everyone’s input has been very helpful.You should start a conversation with Mark Jacobs (@mksj ) who builds VFD control systems for lots of people here on H-M. He has posted many times with detailed designs and schematics and is very helpful and a genuine nice guy. He built the control systems for my PM-935 and my PM-1340GT. If you want to make your own professional looking control panels, this is easily done through this company: https://www.frontpanelexpress.com/

I designed and they fabricated the custom control panels for my machines as shown below:

View attachment 475167

View attachment 475168

View attachment 475169

I prefer some of the controls at waist height mounted to the knee and others mounted on the side of the J-head. The knee mounting is described here: https://flic.kr/s/aHBqjzyRHz

I was thinking something simple like this also .I went the simple route. I wired the VFD between the A/C coming in, and the motor. I made a small box that housed an on/off fwd/rev switch, a speed pot, and a e-stop/power light that I put on the head to replace the original switch. I mounted the VFD inside the base.

View attachment 474748

- Joined

- Jun 12, 2014

- Messages

- 5,071

David's system is more high level, those type of systems I sometimes make as one off types. If you are just looking at the basics, in a smallish box mounted on the headstock, it is not too difficult to do. A few things that you will most likely want is monetary run buttons for the stop red button (unshielded) and start green button shielded, a sustained rotary button for reverse, and a speed pot. another easy trick is to add a switch that is activated by the back gear which reverses the for/rev signals (so when in back gear forward is still forward). Adding a tach and ring light is worthwhile. David posted his design and I also have some that I did the the 935 and 949 mills. You can make a nice front panel like David's, we both use Front Panel Express but they run about $100 these days. I can point you to recommended parts and sources, Automation Direct is a great source and reasonable. I just have my own build preferences for my one off systems.

I personally prefer the control buttons on a pedestal mount or attached to the knee.

Tachometer in this picture is a Tachulator, but in general I just use a standard tach with a NPN sensor built into the light ring.

I personally prefer the control buttons on a pedestal mount or attached to the knee.

Tachometer in this picture is a Tachulator, but in general I just use a standard tach with a NPN sensor built into the light ring.