- Joined

- Jun 16, 2016

- Messages

- 221

Excellent! I am glad you is working out for you with the added bonus of FUN. You are doing something most of us would not even consider. If you could add pictures of your work we'd greatly appreciate it. Photos really add a lot to the story, particularly for those of us that are more than out of our element. Keep up the good work.

Thanks for the encouragement. When I have something picture-worthy I intend to post it.

I think I've worked out how to make the change-over from gears a clean swap. I'm waiting for a few more parts, then I'll be making brackets for the stepper motor and rotary encoder to mount them on the banjo in place of the change gears. Timing pulleys will replace the screw and spur gears. Belt tensioning will be accomplished with the banjo. That will keep everything looking neat, fit under the cover, and be worth taking pictures of. It will also make it easy to change everything back.

I'm going to start with a 5:1 reduction between the stepper and the lead screw. With the stepper spinning 1000rpm (half max) the carriage will move the full length of the bed in under a minute, which seems fast enough to me.

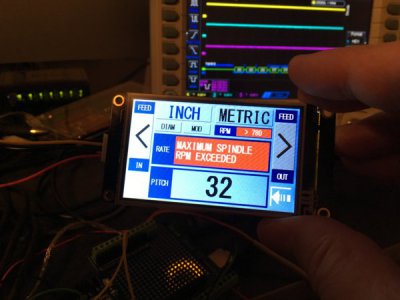

I picked up a 2.8" color display with a resistive touch screen that I think, along with a knob, will make a good user interface. After I got the display I read something that implied that it used up all the Arduino's pins, but after looking at the schematic I don't see a problem.

Initially I plan to make it function purely as a continuously-variable gearbox. I suppose it will have to have a fast jog function so that the half nuts can stay engaged for metric threading. I like the idea of prompts to remind you where to engage the threading dial for a given pitch. What else do you think would be useful?