The LMS 4200 is indeed a physically metric machine, as it was made

Thanks. No power cross feed! It is clear that they put an Imperial, 16TPI, lead screw on the machine. However, this is not uncommon that these are switched from metric to Imperial when sold into the USA.

In fact, the LMS web site for determining TPI,

https://littlemachineshop.com/reference/change_gears.php , requires that you specify whether or not you have a lead screw of 16TPI or 1.5mm pitch.

At this same site it also says: "The normal set of change gears includes the following gears: 20, 20, 35, 40, 40, 45, 50, 55, 57, 60, 65, 80, and 80 teeth." Counting these says that there are 10 unique gears but the 20, 40, and 80 are duplicated. However, when I looked at the gearing plate photo that you shared I found 11 unique gears shown. It show a 21T gear in the metric plate. It would appear that the LMS web side has just left the 21 out. In the photo of

https://littlemachineshop.com/images/gallery/ds/4200 HiTorque 7x12 Deluxe Mini Lathe.pdf I can count 11 gears.

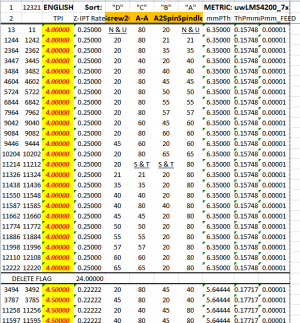

By the way, if it is not obvious, in my spread sheet I refer to the spindle location and the lead screw location as gear axles. In the LMS4200, the "Spindle" column of the lathe sheet would be the LMS4200 lathe's "A" location and the lathe sheet "LeadScrew" column would be LMS4200 lathe "D" Locations. The table or lathe sheet the phrases like "A-A" or "B-B" means the pair of gears on a single axle labeled "A" or "B" while a phrase like "A2Spin" means the gear that is in contact with the gear on the the spread sheets A axle. So the LMS4200 effectively has 3 axles, where the "B" and "C" notations represent the 2 gear locations that are one axle and are turning together.

I added the gears 21 and 57 to the spread sheet and reran the program last evening. Without duplication it found 12,321 gear combinations, not too bad as it only took a while to run. Of course very many of these are not available to you due to the the lack of duplicate gears or combinations which will not physically fit. (I have seen some lathes where the gear combinations and the gear levers yield a lot more combinations and can take a hour or more to create the list.)

I suppose if I knew exactly which gears you have and how many of each one, we could write a macro which would remove the arrangements which are unavailable. I may think about this a bit more. (Do you have 11 gears plus duplicates of the 20, 40 and 80?) Likewise, if one were to come up with rules about which gears do not physically fit these could be found. However, this later endeavor would probably be much more difficult. The former would be a macro that is some what specific to the lathe model.

You can add the gears to the workbook sheet "uwLMS4200_7x" that was posted yesterday and see. Don't forget to put the "Zzz" flag at the end of the column of gear values. The macro watches for this flag. Or, if you like I can re-post the work book with the additional gears.

The Standard Threads table attached as pdf. One can adjust the approximation limits for each thread that was searched and change this table. If you cannot find a gear arrangement that works just adjust the approximation. See sheet tab "uwSrchList." The 21TPI gear improved the number of approximate Metric pitches that could be found. You might have noticed that one can get far more exact metric pitches if he has a gear with 254T, or a sub-multiple of the number . This is the result of 1"=25.4mm. The fact that the lead screw is non-metric causes the need for this gear. However, since 127 = 254/2 it also works. Since 127T is a prime number and the gears must have an integer number of teeth, we can use no smaller value. However, the 21T gear is close. 21*6=126. It is only off by 1/127= 0.79%. Hence, most of the metric Pitch tables provided by the lathe manufactures are not exact, even though they write them out as such! So even though some folks think they need specific gears to generate an exact thread value they are commonly using approximations at the manufacture's recommendations and do not know any better, especially for US lathes the metric pitches.