OK test time.

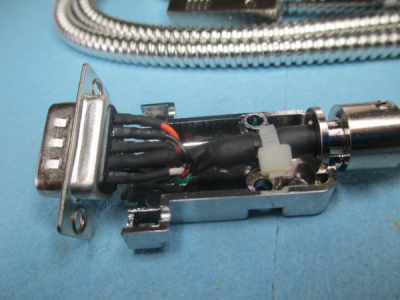

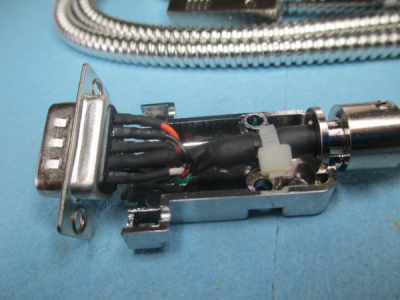

I ordered this with flying leads, but they shipped it with a 9 pin D-sub. No problem, I have wire cutters.

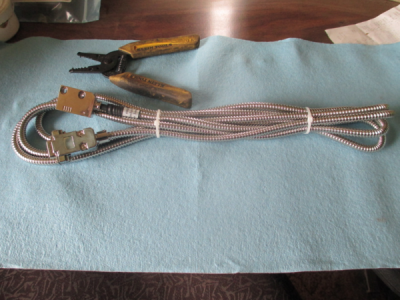

The wiring looks very professional. The cable is high quality with 4 twisted pair, with both foil and braid shielding.

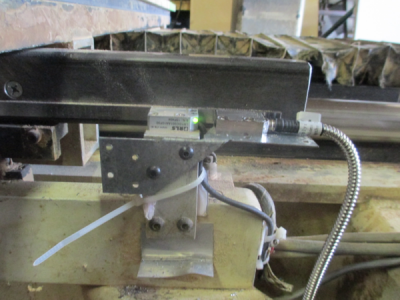

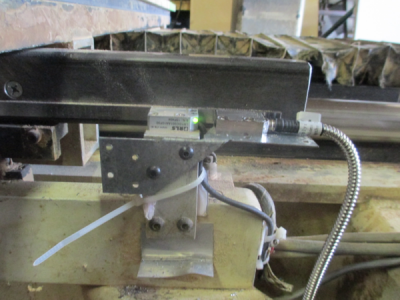

Here is the setup. First find a hurricane tie and modify to become a read head bracket. Fortunately I had enough extra length on the tape to accommodate the extra head.

I had a bit of trouble setting the spacing, the Ditron head is a bit more sensitive to spacing than the Renishaw. I wired the Ditron into the W axis on the machine, that way I could read it on the DRO.

The test consisted of running the router from 0 to 96 inches and back for a bit over an hour. Then will compare the Ditron position to the Renishaw position on the DRO. I don't actually know it either encoder is reading the absolute position correctly, all I can do is compare the readings.

I do have a high degree of confidence in the Renishaw reading because I have been able to hold +/- 0.001 on machined parts on the router, and < +/- 0.0005 on the mill. On Alloys Shizuoka, equipped with the same Renishaw readers, we were able to achieve 1um roundness in circular interpolation, on a 4 inch circle. This was checked with a 1um resolution CMM. In that case we were looking for deviation rather than a specific size, but as near as I could measure it with calipers, it was exactly on size.

I zeroed out both encoders, and pressed Go

Here is the test G-code

%

G0 Y96.0

G0 Y0.0

M47 (repeat)

%

The best speed I could maintain reliably was 150 IPM, but I did take it to 200 IPM during the test, I really need bigger motors on my router.

So at the end of the test, about 10,000 total travel inches, the Renishaw was reading -0.0001, and the Ditron was reading -0.0007. Yeah, I can live with that.

I'm going to call this a success.

I'll leave the Ditron connected and do some comparisons on the next job I run on the machine.

.

.

The wiring looks very professional. The cable is high quality with 4 twisted pair, with both foil and braid shielding.

The wiring looks very professional. The cable is high quality with 4 twisted pair, with both foil and braid shielding.